Tooling & Workholding

Filter by Process Zone:

Cutting With A Purpose

Founded in 1896, Bico Steel prides itself on being a value-add supplier of steel plate and forged steel blocks. Switching bandsaw blades helped the Michigan company prove its worth when asked to quickly deliver product for ventilators early in the pandemic.

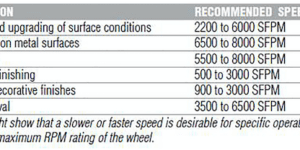

Troubleshooting 4 Common Cutting Wheel Problems

Shops can save time and money — and reduce safety risks — when products are used properly. Here’s what to look for and how to correct it to get the most life out of yours.

Tooling Program for Citizen Automatic Lathes

Platinum Tooling Technologies expands its product line with Heimatec live and static tools for most Citizen lathes. Designed to optimize the machine’s parameters, the precision tools are efficient and cost-effective.

Inserts Make Hard Turning More Cost-Effective

Polycrystalline cubic boron nitride (PcBN) mini-tipped inserts are a great way to lower per-part cost when turning hardened steel components. Kennametal´s two grades of double-sided PcBN inserts increase productivity and extend tool life when machining materials up to 65 HRC.

Tooling Supports More Versatile Long-Grooving

Dormer Pramet targets turning center and lathe applications with an insert, two geometries, a grade, blades, and tooling that support parting-off and grooving. Double-edged insert supports 60% capacity over the LCMF16 insert.

Advanced-Grain Nonwoven Belt Improves Stainless Steel Finishing Process

Finding people who are willing and able to press metal against an abrasive belt all day long can be challenging. Nonwoven belts make the job more appealing by increasing productivity without increasing effort.

Industrial Magnetics, Inc. Welcomes Regional Manager

Navy veteran Aaron Evans is IMI’s new Western U.S regional manager.

Quick-Change Compensating Collet Chuck

Featuring a compact outer diameter and shorter than conventional compensating chucks, MicroCentric’s chuck has a collet with a floating seat that enables the holder to compensate up to 0.060-inch (1.5 mm).

Two-Collet Chuck Doubles Turret Station Capability

EXSYS expands the Eppinger Preci-Flex modular tooling system with a chuck that doubles the machining capability of Mazak’s Quick Turn turning centers. For instance, a tap-and-drill or spot-and-drill combination is easy to set up.

Slim Line Chucks Enhance 5-Axis Milling Versatility

Emuge addresses the increasing complexity of workpieces with a line of FPC Slim Line mill/drill chucks that provide easier access, especially in confined areas and for challenging angles, to maximize machining productivity.