Tooling & Workholding

Filter by Process Zone:

A Bevy of Chuck Accessories To Shorten Machining Cycle Times

Dillon Manufacturing’s chuck jaws provide multiple radiuses for both inside and outside clamping, making them ideal for any size run. Four jaw and/or accessory options lower tooling costs by increasing productivity and extending service life.

As Machine Technology Advances, The Chuck Must Follow

Just as the right workholding can improve your bottom line, inappropriate workholding can eat into profits. Make sure the chuck that came with your lathe isn’t keeping the machine from delivering the throughput and increased capacity it’s capable of.

The Co-Act That Redefines Human-Robot Collaboration

A milestone in safety, SHUNCK’s EGL-C long-stroke grippers feature an algorithm that protects employees as they work beside the robots–robots that happen to have 300% more gripping force than most of their peers.

Redesigned Machining Block Spindle Is 25% Faster

An AC inverter drive on the BEX 15 high-speed block spindle from Suhner Industrial Products increases spindle speed to 23,000 rpm at 87 Hz. Two slide-assembly mounting options enable multiple operations.

High-Speed Milling Spindle Enables Lights-Out Machining

NSK America’s electric i-Speed5 spindle system eliminates the need for motor cables or air tubing. Variable-speed system integrates with control system for complete tool changeability.

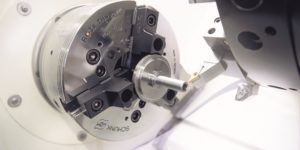

Power Chuck Saves Spindle Wear and Tear

SMW Autoblok’s HFKs-2g high-precision power chuck delivers twice the grip force than standard 3-jaw chucks. Use it for high volume lathe and mill turn center applications including heavy-duty precision machining of easily deformed workpieces.

Custom Full-Grip Jaws Securely Grip the Workpiece

Special pie jaws from Dillon Manufacturing are designed to reduce part distortion by distributing gripping pressure across the workpiece. Customized to your specs for height, diameters, materials and configuration, they’re offered in a choice of four serrated designs.

High-Production Former Lowers Cost Per Thread

Walter USA’s TC470 Supreme thread former combines a new geometry with more forming edges than comparable formers. Coating and surface treatment increase tool life, productivity, and process reliability in high-volume machining.

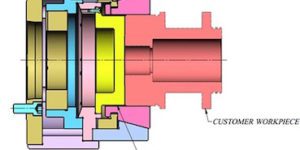

Versatile Collet Chuck System Outperforms Conventional Jaw Chucks

Speedgrip Chuck Company’s standard external collet chuck system combines the benefits of high-precision workholding with in-stock availability to increase precision and productivity.

Change Chucks in Under 3 Minutes with Switching System

SMW Autoblok’s CCS adapter increases operator productivity by providing automatic push-off and easy mounting to traditional or custom workholding including 2-jaw chucks, 3-jaw chucks, collet chucks, mandrels, and manual fixtures.

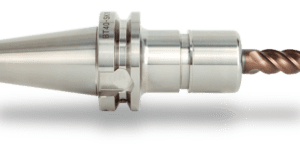

Collet Chucks Provide Flexibility Without Compromising Runout Accuracy

Available in a wide variety of toolholder lengths and diameters for optimal rigidity and clearance, Samchully Workholding’s SK series provide 1 micron runout accuracy as well as three times better runout repeatability and double the gripping force of a comparable ER collet chuck.