Tooling & Workholding

Filter by Process Zone:

Easy Wins: Adapting to a New Manufacturing Reality

As many fabricating and metalworking companies seek to revitalize production in these trying times, a new sense of urgency is prompting creative approaches to automation. While each shop will forge a unique path to its own new reality, they’ll share common challenges and solutions.

Shrink Fit Machine Heats Chuck Only Where You Want

The Power Clamp Preset NG from Haimer features a new generation coil that adapts to the size of the shrink-fit chuck. With 13 kW power, it’s made for solid-carbide and HSS tools from 3 mm to 32 mm in diameter.

First Indexable Drill For 7xD Hole Depth

The CoroDrill DS20 indexable drill from Sandvik Coromant offers reliability and predictability for longer tool life in four 7xD applications. Replacing the CoroDrill 880 and CoroDrill 881 tools, the DS20 can improve tool life up to 25 percent.

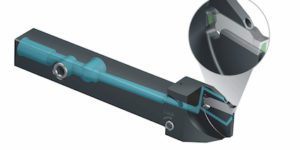

New Grooving Toolholder Ideal for Small-Part Machining

Change inserts approximately 70% faster with Walter’s G4014-P groove turning holder and double-edged DX18 indexable inserts. ‘SmartLock’ feature enables users to access the clamping screw from either side.

Laser-Based Sharpening Facilitates Machining of Ultrahard Cutting Tools

The VLaser 270 completes Vollmer of America’s range of grinding and erosion machines for tool manufacturing. Fixed-beam laser machines polycrystalline diamond (PCD) into highly precise cutting tools for chip guide notches and chamfers.

Superior Abrasives Offers Custom Flap Wheels

Can’t decide which material, grit pattern, mounting option, and/or other attribute is appropriate for a particular application? Superior Abrasives provides recommendations for more efficiently processing the workpiece.

Modular Toolholder Simplifies Swiss-Style Machining

Seco Tools’ quick-change system enables fast, easy, and repeatable insert indexing and tool changes outside of tight machine work spaces. Both cutting heads and inserts can be removed as a single assembly for quick indexing and reinstallation.

New-Generation Taps for Hardened Steel and Cast Iron

Emuge Corp.’s A-H taps penetrate materials up to 48 RC hardness. Available with or without coolant thru-holes and with TiCN coating or NT nitride surface treatment for longer tool life.

Toolholder System Improves Shoulder-Grooving Performance and Reliability

Designed for high-volume production via CNC lathes and multispindle machines as well as automatic lathes, Walter’s G4014-P grooving toolholder and MX22-2L/R indexable inserts with two new geometries provide stability, precision, and indexing accuracy.

Compensation Nuts Quickly Correct Runout Errors and Misalignment

The newest version of Monaghan Tooling’s Reamtec easyZERO nuts feature six adjustment screws that allow for more accurate machining. Users can correct runout errors and misalignment for all round tools with virtually no scrap.

Workholding Bundles Facilitate 5-Axis Machining

Kurt Manufacturing’s pre-engineered Pyramid bundles enable clamping of three components in one fixture in a single setup. They’re standard for 12 5-axis vise models and handle parts from 2 inches to 7 inches.

Roll Form Taps for Medium-Strength Steels

Designed for forming threads with improved surface quality, Emuge Corp.’s Innoform–Steel-M line of HSSE-PM taps increase static and dynamic thread strength in medium-strength steels up to 44 HRC.