Tooling & Workholding

Filter by Process Zone:

Two New End Mills from Kennametal

A 4-flute, solid carbide end mill delivers superior performance for steel, stainless steel, high-temperature alloys, and cast iron. A 5-flute end mill maximizes aluminum roughing for aerospace machining.

Hoffmann Group Expands PPC Tool Family

Parabolic performance cutting (PPC) product family expanded to include copy milling cutters with indexable insert; PPC solid carbide barrel milling cutters optimized for high-alloy and hardened steels.

Mill a Deeper Path with New Inserts and Cutters

Dormer Pramet adds to its milling assortment for die and mold with the double-sided SNGX11 insert for machining corners inside a pocket and SSN11 cutter available in diameters from 1.26 in to 4.92 in.

Inserts Make Back Draft Milling More Efficient

The latest addition to Dapra Corp.’s EDGE² SBN finishing system, SBD inserts are designed to help operators finish back draft jobs more accurately and with fewer insert changes. Available in two premium coatings, they’re interchangeable with SBN series twin-edge ball nose inserts.

Three Announcements from Big Kaiser

The company is manufacturing basic arbors (shell mill holders, end mill holders, shrink fit, and blanks) in inch sizes for the North American market. Three new accessories increase in-process efficiency by automatically cleaning workstations and workpieces.

Benefits of Using a 5- or 6-Inch Grinding Wheel or Flap Disc

More fabricators are using larger-diameter grinding wheels and flap discs for their grinding, material removal, and blending applications instead of 4.5-inch options — and with good reason.

ANCA Updates ToolRoom RN34 Software

In addition to several new tool types, the package reduces setup time from hours to 5 minutes via a new tool-balancing feature and provides an intuitive interface for creating complex endmill geometries that minimize chatter. For example, the constant-helix ballnose option is replaced by a graphical drag-and-drop designer with optimized irregular helix curves to reduce vibration and near-instant visualization by switching from 2D to 3D projection of the cutting edge.

Drum-Based Tool-Changer Provides Flexibility in a Small Footprint

The increasing demands placed on cutting technology are leading to an increased need for more advanced machine tools. Engineers in Germany have automated a magazine capable of storing and deploying up to 9,000 tools using PC-based control, EtherCAT, and dynamic motion control.

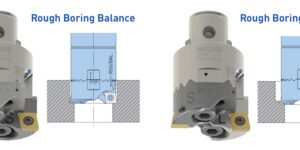

Selecting the Right Lead Angle and Insert for Boring Tools

The rules for twin-bore roughing and single-point fine boring are similar – but not the same. Lead angles close to 90 degrees more effectively combat potentially damaging chatter and vibration because they apply the least amount of radial pressure against the tool.

Record Sales of Collaborative Robots Reveal Increasing Demand for End-Of-Arm-Tooling

Annual installations of collaborative robots (cobots) grew 23% from 2017 to 2018, according to the World Robotics Report, published by International Federation of Robotics.

Flatten and Form Metals with Combination Anvil and Bench Vise

Palmgren takes a fresh design approach with new model #9629749.