Tooling & Workholding

Filter by Process Zone:

TAP FOR HIGH-STRENGTH STEELS AND TITANIUM ALLOYS

Dormer Pramet’s Shark Line grows with the addition of the Black-ring tap.

ATEX-CERTIFIED DRILLS PROTECT WORKERS IN POTENTIALLY EXPLOSIVE ENVIRONMENTS

Exclusive protection on the rotating chuck prevents tools from becoming a potential ignition source.

ALLIED MACHINE EXPANDS BORING TOOL LINE

Products reduce vibration in large-diameter applications and increase efficiency by simplifying insert changeout.

OnRobot Grippers Receive UR + Certification for Seamless Operation

The certified URCap software provides a unified interface for OnRobot’s new versions of RG2, RG6, and VG10 grippers with Universal Robots (UR).

New Sales Manager Joins Tooling Tech Group

Nate Ruhenkamp heads the sales team for compression and thermoform offerings.

Starrett Appoints New VP of Metrology Systems

David Allen has been tapped to lead the high-end metrology businesses for the Athol, Mass., manufacturer.

Intelligent Toolholder Controls the Cutting Process in Real-Time

The smart iTENDO hydraulic expansion toolholder from SCHUNK enables real-time process monitoring and control of geometry and performance data directly in the tool.

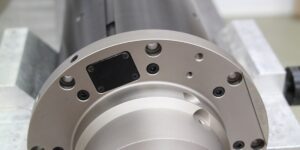

Electro-Spindle Monitors Cutting Processes in Real-Time

The e-SPINDLE from PCI / Absolute Machine Tools integrates sensors and actuators to monitor cutting processes and adjust parameters to optimize tool life and part quality.

More Aggressive Than Ever

Whether the stock removal involves blending, grinding, cutting, cut-off, notching or deburring, many of the newest types of abrasives are more aggressive in their surface conditioning capabilities – and in helping to reduce your operating costs. Here are some of the ways they do it.

Diamond Grinding Discs for Superior Stock Removal on Difficult Materials

Mosaic diamond grinding discs from Buehler effectively and consistently grind steel, sintered carbides, alloyed metals, thermal spray coatings and other hard materials with an improved material removal rate that reduces operating costs.

Disc Brushes for Automated Finishing in CNC Machines or Robot Cells

Ideal for automated deburring, edge filleting and surface finishing of milled, flat precision parts, Garant disc brushes from Hoffmann can also finish machining valve plates with internal labyrinths and brush down smooth surfaces on parts produced by sintering, punching, die-casting or pressing.

How to Lower the Costs of Cross Hole Deburring, Manual and Automated Honing

Ideal for use in automotive, marine, oil and gas, aerospace, pump and valve applications, long life CrossFlex honing brushes from Weiler Abrasives provide a surface finish free of metal burrs.