Tooling & Workholding

Filter by Process Zone:

BIG KAISER Moves Production of Smart Damper to U.S.

They can now provide more variation and faster delivery of special lengths for specific applications.

Stronger Band Saw Blades and a Web-Based Blade Selection Tool

Versatix MP bi-metal band saw blades and the web-based Band Saw Blade Selection Tool from Starrett help shops improve productivity and reduce costs when cutting structural profiles, bundles and other sawing applications.

Expanding the Magnetic Field in Shop Operations

Advanced magnetic systems from Master Magnetics ensure safety and speed for material handling, workholding and shop cleanup activities.

Magnetic Sheet Fanners, End-Of-Arm-Tooling for More Efficient, Safer Press Room Operations

Magnetic sheet separation fanners and magnetic end-of-arm-tooling from Industrial Magnetics are ideal for handling sheet metal, metal blanks, stampings and parts in office furniture, appliance, stamping, fabrication and other applications.

How to Increase Productivity and Efficiency in Production Stamping

The Fibro Electronic Tapping Unit and the Wireless Pressure Monitoring from Fibro enables production stampers to add value, increase throughput and improve operational efficiency.

In-Die Tapping of AHSS Material and More

Jarvis Cutting Tools works directly with machine builders to develop exclusive high-performance taps that address current and future production requirements.

Mechanical and Servo Style In-Die Tapping Heads

In-die tapping head technology from Hutchison Tool provides a tapping range from #2-56 to 1-1/4-12 or metric M2 to M30 that run in press strokes from 3 in to 20 in.

How to Eliminate the Need for Spot Welding and Riveting

One simple, high-cycle punch and die operation automatically feeds, punches, inserts and locks the self-piercing FAS-NER from AKH to produce a solid joint in similar or dissimilar metals and thicknesses.

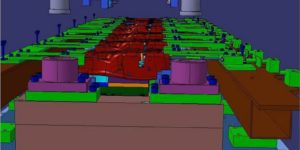

Single Source Capabilities for Die Design Through Manufacturing

Tooling Tech Group is a single source supplier of everything from die design, simulation and engineering through to die build, repair, try-out and production stampings.

Spring Force Wedge Clamps Allow Clamping Without Permanent Hydraulics

Hilma self-locking wedge clamps from Carr Lane Roemheld are powered by spring force that is ideal for clamping dies with a straight clamping edge, for metal stamping die change or plastic mold change.

Unique Finishing and Deburring Tools

Brush Research Manufacturing provides Nampower abrasive disc brushes for general purpose, medium and heavy deburring applications, and Flex-Hone CBN abrasive for difficult-to-finish materials.

Robotic Grippers for Efficient Tending of Metal Fabrication Operations

The RG2 Collaborative Gripper and the VG10 dual-zone electrical vacuum gripper from OnRobot provide dual grip capabilities, flexibility and more to optimize handling and cut machine tending time.