Tooling & Workholding

Filter by Process Zone:

Power Tools and Accessories for Metalworking

A new catalog from Metabo features detailed specifications for metalworking, cordless systems, accessories and specialty and problem solver tools.

U.S. Cutting Tool Orders Slow

Orders of $206.3 million were down 1.9 percent from the previous month.

Do More, Spend Less

Trying to find ways to cut more in a single setup without having to purchase new machines? These rotary tables can provide an affordable way to increase the productivity of your vertical machining centers.

Heavy Duty Tables Add Four-Axis Capabilities

Rugged HRT Series of T-slotted rotary tables from Haas can be mounted vertically or horizontally for added versatility in machining medium to large parts or fixtures.

Small, Powerful Plug-and-Play Rotary Tables

Compact, rigidly built rotary tables from KME CNC provide tremendous torque capacity and easily integrate with vertical machining centers to expand three-axis capabilities into four-axis, or four-axis capabilities into five-axis by simply mounting the rotary table right on any pallet.

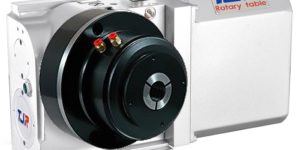

Collet Rotary Table is Affordable Alternative to Chucks

Instead of using 3-jaw or 4-jaw chucks, the TJR AR-5C Pneumatic Collet Rotary Table from CNC Indexing & Feeding Technologies provides a highly rigid, accurate way to grip and index products suited for 5C collets.

Big Bore Rotary Tables for Large Part Machining

For machining large diameter parts used mainly oil/energy applications, the Tsudakoma RCB Series extra-large center bore, dual disc hydraulic clamping rotary table from KOMA Precision uses a proprietary dual-lead worm gear system with ultra-precision cross roller bearings to deliver optimum balance between power, durability and smooth cutting performance.

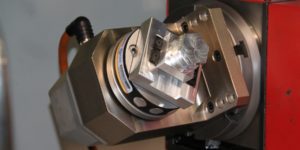

Rotary Table Workholding With Automated Hydraulic Clamping

Ideal for three-axis vertical machining centers, the Rotary Table Workholding System from Kurt uses a DX6 CrossOver Hydraulic vise with a trunnion mounted onto a 4th-axis rotary table to provide three-side access to the part to be machined.

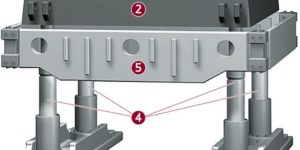

Modular Die Cushion System Extends the Life of Deep-Drawing Dies

The Modular Die Cushion System from Moog improves process reliability, reduces commissioning time, offers flexible layout options for integrating the manifold and requires comparatively little piping to help press rooms lower their maintenance and piping costs.

Online Equipment Monitoring Drives Productivity Improvements

The CoroPlus MachiningInsights digital system from Sandvik Coromant collects data directly from a connected machine tool and input from operators, making it possible to visualize machine and tool utilization levels online through a web browser and collaborate to make improvements within the factory.

Tool Measuring Systems and RFID Working: A Powerful Combination

Efficiently moving information around your shop floor is more important than ever. Connected through RFID, a shop can now use a tool presetter to monitor things never monitored before and use that data to fine-tune processes, reduce inefficient costs like scrap and waste, and make the factory floor smarter, streamlined, far more efficient and competitive.