Tooling & Workholding

Filter by Process Zone:

Tips for Successful Hole Sawing

Hole sawing may seem straight forward, and it can be. But for optimal results, following some tips and guidelines for selecting and using hole saws is recommended. In fact, fabricators who are adept and knowledgeable about band sawing can apply some of these same strategies when hole sawing.

Choosing the Right Shear for Your Application

Five different types of shear grinds for punch press tooling can reduce the amount of punching force required, increase tool life when side loading is not a concern, and minimize the amount of wear on the machine. Here are some tips on how to choose the correct option for a specific application.

Finishing Stainless Steel: The Ten Essentials

Finishing stainless steel is expensive because it requires a significant amount of time, more skilled labor, and mistakes can have a big impact on quality and productivity. To maximize efficiency and your bottom line in achieving any finish – whether it be a #4 sanitary finish or a #8 mirror finish – be sure to follow these ten best practices.

Suhner Partners with Velocity Products

They work together to provide repair and maintenance of SU-matic tooling for Okuma and other machine tools throughout North America.

Roll-Kraft Installs New Parts Washer

This new unit should increase their efficiency in preparing incoming rolls for regrind.

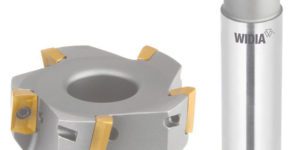

Advanced Milling Grade for High Temp Tough Superalloys

The cobalt-rich substrate in the new WS40PM indexable milling grade from WIDIA makes it a first choice for machining titanium and other superalloys.

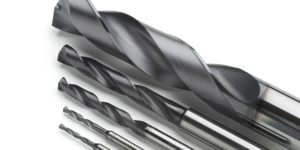

A Whole Lot of Holemaking

With metalworking business booming in all market sectors, both fabricators and machinists are drilling and finishing more types of holes than ever, faster, deeper and with more precision in a widening variety of materials. Here is some of the latest equipment and tooling to help them drill and finish more accurate and consistent holes, with higher reliability and longer tool life.

Rex-Cut Invests in New Manufacturing Line

Nearly $1 million in new capital equipment will manufacture proprietary abrasive material used in their grinding, blending, and deburring abrasives.

Innovative Clamp Streamlines Difficult Welding of Automotive, Aircraft, Consumer Goods Applications

TCC-2E Tolerance Compensation Clamps from Destaco eliminate the need to manually adjust clamps for different sheet metal thicknesses or tighter tolerances.

Weiler Abrasives Appoints New Specialists

David Jescovitch and Ron McCarthy will focus on pipeline construction, shipbuilding and large metal fabrication applications.

How to Generate More Holes Faster and with Fewer Required Drills

Combining new geometry and new coating with strong point geometry, the Feedmax –P drill from Seco Tools lets shops run machine tools to their full drilling potentials.