Tooling & Workholding

Filter by Process Zone:

Coolant-Thru Micro Toolholders

With increased use of micro tooling that operates at higher speeds in more compact tooling zones, Ti-Loc micro end mill holders and other coolant-thru capable micro toolholders from GenSwiss help solve the need for more efficient machining operations while extending tool life.

Punch Tap Technology for Faster Threading

The Punch Tap from Emuge produces threads extremely fast in a single synchronous, helical movement of feed and rotation, creating a shortened tool path that produces internal threads in under half a second, using significantly less energy during machining.

Shaper Up for Socket Machining

The Shaper Duo system from NTK Cutting Tools cuts into the material with up sharp corners, creating less tool pressure than rotary broaching for hexagon sockets up to 12 mm, square up to 8 mm sockets, and 6-lobe socket machining for T6 up to T30.

One Cutter, Many Choices: Versatility in Indexable Milling

With 54 options in a single cutter, the ISOD05 cutter from Dormer Pramet expands indexable milling with an adaptable option to support a wide range of insert shapes and operations from roughing to finishing.

Industry 4.0 Tooling Technology Couples with Advanced Cutting Tools

Power Clamp i4.0 series shrink fit machines from Haimer are network compatible and Industry 4.0-ready for communication of tools and machines on the shop floor, with tool scanning capabilities to read and automatically set the shrinking parameters via Data Matrix codes.

High Performance Taps, Drills and End Mills

GARANT MasterTap from Hoffmann guarantees reliable thread machining in a wide range of materials, including steel, stainless steel, aluminum, brass and cast iron.

SCHUNK Appoints New Director of Sales for the Midwest

Matt Steele now directs sales of tooling and workholding systems to end users and sales channels in the Midwest.

ALM Positioners Supports Campaign for Kids

Product manager Colten Brunenn is supporting “Over the Edge for Kids’ Sake” to raise funds for Big Brothers Big Sisters of the Mississippi Valley.

Seco Tools Names New IT Director

Jeff Bowden is their new director of information technology.

Weiler Abrasives Expands U.S. Operations

Lean manufacturing and factory automation opened capacity to consolidate and increase power brush manufacturing in their Cresco plant.

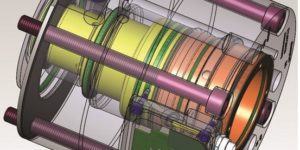

Multi-Sensor Unit for Drawbar Inspection

The MSU sensor system from Advanced Machine & Engineering combines a distance measurement system, a piston position monitor, and optional leakage detection into one compact, built-in multi-sensor and electronic evaluation system in the unclamping unit of a drawbar.

High Speed Spindles for Milling, Cutting and Grinding Applications

For medical and dental machining applications, the 62 mm HF 62 high speed spindle from IBAG offers speeds to 140,000 rpm, is suitable for automatic tool changing operations, and utilizes the P6 Collet System.