Tooling & Workholding

Filter by Process Zone:

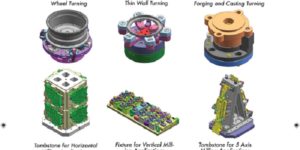

Turnkey, Custom Engineered Workholding Services for Prismatic & Turning Machining

Kitagawa North-Tech provides turnkey systems for machine shops that face productivity challenges or specific machining problems in their vertical, horizontal, multi-axis prismatic milling and turning, forging and casting operations.

One Closer, Four Work Holding Systems

Flex Grip closers from Lexair can boost productivity in 4-axis, 5-axis, rotary indexer and stationary machining operations by reducing set up times with 10 second collet change capability and .0002 in part accuracy.

Magnetic Safety System for Easier, Safer Front Loading of Punches on Press Brakes

The Maglock magnetic safety system on American Precision Style press brake tooling from Mate Precision Tooling attaches and seats the punch to the holder with no separation between the surfaces. Punches install facing forward or backward with magnetic power and simple tangs for front loading.

Superabrasive Wheels Grind Difficult Materials Substantially Faster

HPL Grinding Wheels from Meister Abrasives combine high-end CBN crystals fixed with durable, porous, intrinsically lubricated bonding matrix to allow substantially faster grinding of difficult materials.

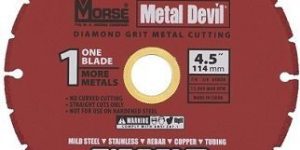

Devil in the (Metal Cutting) Details

Metal Devil Diamond Edge Cut-off Wheels from M. K. Morse dissipate heat fast for long life and faster cutting of metal studs, structural steel, stainless tubing, rebar and cast iron, and more on high rpm angle grinders, circular saws, gas powered saws and abrasive chop saws.

Instant Access to Help with Tooling

With the free Ifind app from Sandvik Coromant, purchasers, engineers and machine operators can instantly access extensive information about the entire tooling process, from selection to sourcing, including tool information, recommendations, availability and prices.

Parallel Keepers Provide Unparalleled Grip for Workholding

Hardened steel Parallel Keepers from STA-PUT123 offer an unparalleled grip for holding small parts down to 1/8 in, as well as the largest part that will fit in a full open vice.

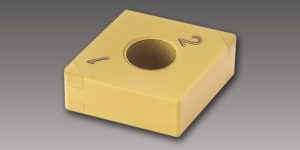

Inserts for High Precision Hard Turning and Hardened Steel Machining

The BNC2010 Grade from Sumitomo is designed for high precision hard turning, using a CBN substrate coated with a TiCN layer to achieve excellent surface finish while reducing wear.

High Performance Cutting and Grinding Tools for Demanding Pipeline Welding Applications

The Tiger bonded abrasives line of tools from Weiler Abrasives includes Roughneck combo wheels for pipeline cutting and grinding, Tiger Zirc grinding wheels for aggressive grinding jobs, and thin Type 1 and Type 27 Tiger Inox cutting wheels for accurate, clean cuts with a contaminant-free bond for worry-free stainless steel applications.

The Need for Fine Hole Finishes and High Productivity Rates

The Top Ream carbide reaming system from WIDIA uses a single carbide disc and brazed joint for a strong connection that is inherently more stable, resistant to vibration and virtually immune to thermal effects during machining operations.

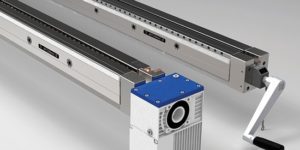

Crowning Deflection Control System for Press Brakes

The Express Crowning system from Wilson Tool helps control deflection or “the canoe effect” in press brake applications over 4 ft long with quick, repeatable crowning that is precisely adjusted by a basic hand crank and digital readout or an electric motor driven by the CNC machine control.

Combination Cutting/Grinding Wheels for Heavy Duty Fabrication

Norton Quantum3 Combination Wheels from Saint-Gobain Abrasives provide 50 percent longer life that significantly reduces the need for wheel changes, resulting in decreased production downtime, less operator fatigue and lower labor cost.