Tooling & Workholding

Filter by Process Zone:

Wila USA Names New President

Chris Morse now heads up their North American business.

Bridging the Gap Between Long Life and Superior Material Removal in Weld Cleanup

Users of lower-end abrasive brushes in oil and gas and pipe construction work sometimes change out their tools five times a day. They don’t have to anymore: new high performance brushes last long without sacrificing superior cut and removal in heavy or radial deburring jobs such as weld cleanup, root and hot pass, surface preparation, pipe joining and other jobs.

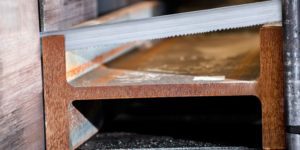

Bi-Metal Band Saw Solutions for Structural Cutting Applications

Cutting large structural beams and tubing can be a demanding application for metal fabricators. New innovations in bi-metal band saw blades can provide the cost-effective solutions they need to meet a range of specialty cutting applications.

Instant Data Transfer of Band Saw Blade Cutting Parameters to Machine

Saw operators can use the Individual Performance Cutting (IPC) custom band saw blades program from Simonds/WESPA to point, scan and transfer a complete, unique data set of machine-specific cutting parameters to the machine to begin cutting.

Versatile Pipeline Grinding Discs Minimize Downtime and Increase User Productivity

The expanded line of depressed-center grinding discs from Osborn includes pipeline grinding discs in Advanced Aluminum Oxide and Zirconia for fast cutting, heavy stock removal, long service life, application material versatility and smooth finish.

Combination Cutting/Grinding Wheels for Oil Rig and Pipeline Manufacturing

Norton Quantum3 Combination Wheels from Saint-Gobain Abrasives provide 50 percent longer life that significantly reduces the need for wheel changes, resulting in decreased production downtime, less operator fatigue and lower labor cost.

Replaceable Single Tip Drill for Small and Deep Hole Boring in Oil and Gas Applications

The BT-A Drill from Allied Machine & Engineering uses a laser clad bearing area for improved straightness and replaceable cutting edges to eliminate the need for resharpening.

How to Provide Uniform Pressure on Jaws for Consistent Bore in Oil and Gas Jobs

Jaw forming rings from Dillon are mounted in direct contact with the top jaw so that the jaw forming ring preloads the chucking system and grips the workpiece more firmly to maximize jaw life for cutting and forming operations, providing uniform pressure on all jaws for a consistent bore.

High-Feed Face Mill Speeds Up Productivity in Oil and Gas Work

Using a 25 deg entering angle for additional productivity gains when milling steel and cast-iron workpieces, the high-feed CoroMill 745 face milling cutter from Sandvik Coromant achieves higher metal removal rates in applications with depths of cut up to 0.110 in.

Vibration-Dampening Tooling for Large Diameter Work in Oil and Gas Applications

With its patented and versatile GL connection, the Steadyline vibration-dampening tooling system from Seco Tools features a polylobe taper-face interface for centering accuracy, 100 percent repeatability and fast tool head exchanges that allow shops to perform both static and rotating operations with the same bar.