Turning Centers

Filter by Process Zone:

Flexible Machining Center Configures to Wide Range of Applications

The compact Hüller Hille NBH P 80 from FFG has a choice of spindles, highly precise and dynamic rotary tables, and CNC controls that allow for flexible configuration. Its chain-type magazine has 60 locations that can be manually loaded during machine operation.

Multi-Process Turning Center

The C1 Multi-Process Turning Center from Hwacheon Machinery uses a triple stack turret with a tool changer to handle a multitude of tools that allow for the precise machining of complex parts with drastically reduced setups.

IMTS 2016: Metal Cutting

Come explore the very foundation of the machine tool industry. This pavilion is where you’ll find the latest innovations in metal cutting equipment, machining centers, turning centers, drilling, boring, milling, and more.

New Generation Vertical Machining Centers

Third generation DNM series VMCs from Doosan Machine Tools are general purpose, workhorse machines for shops that need robust and accurate performance.

Bridge Mills Handle Large Loads in Smaller, Expandable Footprint

Johnford DMC Series double-column moving table bridge mills from Absolute Machine Tools allow for tight machining and tight tolerances during high speed machining of massive loads.

Multitasking Takes Center Stage

A wide range of Nakamura-Tome multitasking turning centers and strategies for machining precision parts was recently displayed by Methods Machine Tools.

Economical Multi-Tasking Turning Center

The Nakamura-Tome AS-200LMY-S sub spindle machine from Methods Machine Tools combines a powerful milling drive with a high speed, high accuracy C-Axis and 82 mm stroke Y-Axis to finish parts and eliminate deburring, milling, drilling and repositioning of fixtures.

Under the Hood: Automotive Machining

New powertrain components. More sensors and electronics parts. Increasing part complexity. Difficult to cut materials. Faster delivery. How do automotive suppliers navigate to profitability through this stormy sea of lightweighting and driverless cars?

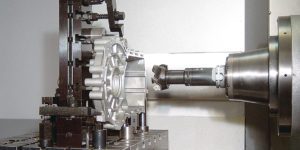

Gearmaking for Powertrains

GMTA offers a full line of Rasoma gear machines in a variety of configurations with full automation for milling, hobbing and shaping applications.

Machining Suspension Brackets, Engine Parts, Gears

Mazak offers a diverse selection of machine tools for machining basic suspension brackets or processing complex engine parts, ready for any shop requirement and reducing cycle time to boost productivity.

High Efficiency Turning of Automotive Parts

With a powerful main spindle and dual servo turrets capable of simultaneous, synchronized control, the LU EX Series of turning centers from Okuma has the power and flexibility to produce parts with the highest level of efficiency.

Agile Production of Crankshafts, Cylinder Blocks

MAG offers the Boehringer 221/226 Cx that is ideal for milling, turn broaching and turning new generation crankshafts, and SPECHT horizontal machining centers with integrated honing technology for boring cyllinder blocks.