Turret Presses

Filter by Process Zone:

New THOR F Combines High Performance Thermal & Mechanical Cutting

THOR F integrates plasma and oxyfuel cutting with an optional beveling system, and an optional tube and profile lathe. It also combines plate cutting with edge preparation and numerous mechanical machining operations, including milling, drilling, tapping, countersinking, marking, etc.

Five New U.S.-made Hydraulic PressPro Models with Improved Features

Scotchman Industries has redesigned its PressPro Series of 5 hydraulic press models to provide customers with the flexibility to move the machines more easily.

CINCINNATI EZ BEND™: Bringing Automation to the Shop Floor Through Collaborative Robotic Technology

Transform your operation with EZ Bend, the easy and innovative way to integrate automation. Free up your press brake operators to focus on complex bends ensuring a smooth and efficient operation for even the most complex tasks.

Big Rapids Products Increases Uptime by More Than 25 Percent with new Servo Press

Big Rapids Products has installed its first AIDA servo press, housed at one of its Mt. Sterling, Ky., facilities.

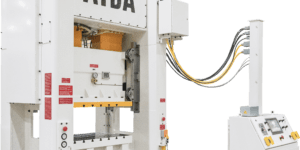

New High-Volume Production Mechanical Stamping Press now Available

AIDA-America introduces its NSX High-Volume Production Mechanical Stamping Press, which features speeds up to 300 strokes per minute.

FABTECH 2023: New Mechanical 110-Metric Ton, 300 SPM Stamping Press

AIDA-America’s newly designed two point, 110-metric ton, unitized frame press is capable of speeds ranging from 120-to-300 strokes per minute.

Increase Your Productivity with Highly Precise and Accurate Solutions

The most innovative and updated features to today’s metal forming and fabricating machinery, additive manufacturing equipment, software, controllers and accessories result in efficiencies — both in production and cost savings.

All-Electric Actuation on Hot Forming and SPF Presses

Utilizing Beckwood’s patented LSP™ technology, new hot forming and SPF presses have an all-electric option that eliminates the need for fluid power systems.

60-ton Electric-drive Press Brake Added to LVD’s Product Line

Dyna-Press 60/20 offers flexibility in tooling. It can be outfitted with universal, Wila or U.S. style punches and universal, LVD or U.S.-style dies.

AMADA’s Innovations Create Total Solutions Ensuring Customer Success

![AMADA AMERICA, INC, AMADA AMERICA, INC., AMADA AMERICA, AMADA, Jason Hillenbrand, Joe Amico, EVS Metal, Michael Weiss, Weistec Engineering, advanced metalworking solutions, lasers, turret punch presses, press brakes, sheet metal fabrication equipment, turret presses, punching, punch laser technology, punch laser, punching machines, auto-tool changing press brakes, EVS Metal, HG 1003, Weistec Engineering, AMADA [VPSS]3i software, metal fabrication industry](https://neighborly-cakes.flywheelsites.com/wp-content/uploads/2022/10/Weistec_BREVIS_1212_AJ_Doors_Open1-300x150.jpg)

AMADA’s sheet metal fabrication equipment assists end users in generating more product by utilizing their existing workforces.

Bull Moose Tube Selects an Ascent Press from Beckwood Press Co.

The new 100-ton press features a 4-point gib guidance system to maintain parallelism throughout the stroke as well as an 18” x 24” working area.

Flexible Solutions Meet Your Forming and Fabricating Needs

Advances and customization of press brakes and stamping presses meet your shop’s high-precision requirements, allowing you to better serve your customers.