Vertical Machining Centers

Filter by Process Zone:

Before You Buy That VMC

When investing in a new production vertical machining center, take time to evaluate these seven critical features that have the greatest impact on the productivity and profitability of that machine tool.

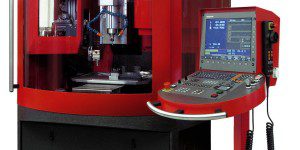

High Speed Ultra Precision Machining

The Ultra Precision EVO CNC Machining center from KERN Precision is equipped for 3-5 axis nano-precision machining of medium to large production lot sizes.

Low Cost Machining of Exotic Materials

The small, reliable, and rugged VMC850E vertical machining center from SMTCL is ideal for North American job shops competing in the world market.

GF Machining Solutions Helps Lotus F1 Team

The Lotus F1 Team invested in six high-performance, cost-effective Mikron HPM 450U 5-axis machine tools with integrated automation to produce its precision, complex F1 car parts in low quantities. These replaced 3-axis milling machines that were not performing at the desired productivity levels.

Sweden is Home to Latest Haas Milestone – 150,000th Haas Machine

The 150,000th machine – a DS-30SSY dual-spindle turning center with Y axis – rolled off the Haas production line January 19, 2014,

Versatile 5-Face Bridgeport VMCs for the Job Shop

Two new 4+1 axis vertical machining centers from Hardinge are designed to achieve maximum capacity and performance in the job shop, OEM, aerospace, medical, electronic, defense, automotive and power generation industries, as well as many other manufacturing sectors.

Easy-To-Use Vertical Machining Centers for Precision Parts

VMC B series machine tools from SMTCL Americas are made of cast steel to machine workpieces up to 1,200 mm with speed and precision.

Machining Center for Producing Precision Graphite Electrodes and Similar Parts

The Tongtai TMV-510G machining center from Absolute Machine Tools has features provided specifically for graphite machining, with an arm-type ATC that keeps tools away from contamination and out of the work zone, and a standard full cover on top of the machine contains dust.

5-Axis Machining Center for Large Parts, Precision Die/Mold and Aerospace Applications

The D800Z vertical machining center from Makino handles workpieces of up to 1,000 mm in diameter and 1,200 kg in weight that can be machined in five axes, with great efficiency and fewer operations for reduced production time.

VMC for Small Job Shops or High Production

The F650 Value Master from Hyundai WIA uses a 25 hp, 10,000 rpm spindle for deep cuts at high speeds and Thru Spindle Coolant for deep hole drilling.

Produce Accurate Aircraft Parts in Single Setups

The VARIAXIS j-500 5X vertical machining center from Mazak provides cost effective and efficient single-machine part processing in titanium, hard metals and aluminum via fast, powerful high-rigidity spindles as well as a high-accuracy rotary/tilt table.

Vertical Machining Center is Ideal for Mold Making

The VMX6030i from Hurco uses an UltiMotion® motion system with travels of 30 in Y-axis, 60 in X-axis, 24 in Z-axis on a working table surface of 66.14 in x 30 in.