Welding

Filter by Process Zone:

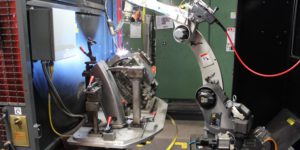

Workcell for Job Shops

The ArcWorld C-30 system from Yaskawa Motoman includes a six-axis MA1440 arc welding robot, DX200 controller with menu-driven arc welding application software, and integrated welding package.

Ceramic Centring Pins for Automated Welding

Cerazur ceramic welding centring pins from Doceram are extremely durable, with high impact strength that is ideal for the very short cycle times of automated production lines, such car body assembly, where even hardened metal centring pins quickly become deformed and worn.

Automated Welding Redefined

The new TPS/i Robotics welding power source from Fronius is specially tailored to the demands of robot-aided welding, with integrated and fully synchronized system components that enable robots to weld faster with a higher degree of repeatability.

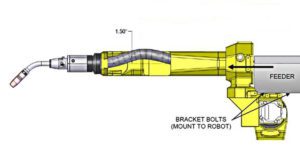

Top Ten Things to Consider with Through-Arm Robotic MIG Guns

Through-arm robotic MIG guns don’t require a mounting arm like conventional robotic MIG guns do. They provide a smaller work envelope that is ideal for working in tight spaces. Here are the top factors in selecting, installing and maintaining a through-arm robotic MIG gun.

A Week in the Life of An Online Data Management System

We can now measure, store and analyze up to 7.5 million weld sessions per day. By automating functions that were once done manually, a shop can save countless hours and provide real transparency into their drivers of productivity, quality and cost control.

Improving Automation with Welding Information

By providing archived data that can be used to lower costs, a welding information management system helps improve the productivity and quality gains offered by automation. This technology helps shops make the most out of their investment in welding automation, increase their competitiveness in the marketplace, and improve their profitability.

Getting Mobility & Smart Connected Devices Right on the Factory Floor

What is the appropriate size of a mobile device to use on the factory floor?

Weathering Steel: Taking the Guesswork Out of Filler Metal Selection

Weathering steel offers excellent resistance to atmospheric corrosion caused by rain, snow or humidity. During the welding process, the filler metal type and the manner in which it is applied determines whether the resulting weld will match corrosion resistance or have the same reddish appearance, more commonly known as color match.

Benefits of Financing Remain with Lease Accounting Changes

The new lease accounting standard by the Financial Accounting Standards Board will not impact shops wanting to acquire advanced manufacturing equipment to grow their business. Here are some of the changes on operating leases for capital equipment that your shop should be aware of and prepare for.

Capital Equipment Financing Jumps in March

This increase in business volume is good news amid uncertainty in the outlook for U.S. economic growth.