Welding

Filter by Process Zone:

Miller Electric Introduces ClearLight™ 2.0 Lens Tech: See Details Like Never Before

Advanced, high-definition optics provide the most realistic view that’s clearer and brighter — before, during and after every weld.

New AWS3 Pneumatic Active Welding System from AMADA WELD TECH EUROPE

This system specifically combines F- and FP-series pneumatic weld heads and weld pincers with an IS-Q-series inverter power supply.

Welding, Welding Automation, Robotics & Industrial Automation, Tube & Pipe

Welding, robotics and automation will be featured at Fabtech in Atlanta.

When is it Time for Fixed, Cobot or Automated Welding?

Taking the time to carefully plan for this investment is important. Look to a provider for assistance and for help determining the expected payback.

AMADA WELD TECH Highlights the TR-T0016A Touch Retract Welding Torch

The torch is made for welding conductive thin-sheet metal and is suitable for welding multiple battery designs in a range of battery pack configurations.

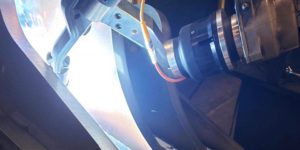

Miller Electric Mfg. Announces the Launch of Hercules™ Welding System

Miller’s new automated MIG welding system provides greater deposition rates and throughput.

Solving Common Causes of Welding Porosity

It’s relatively simple to implement solutions when taking care to monitor the welding process and understand the causes of porosity.

New POWER MIG® 215 MPi™ Multi-process Welder Available from Lincoln Electric

The newest addition to the POWER MIG lineup delivers a range of capabilities in an ergonomically friendly, yet robust design.

Huntingdon Fusion Techniques Updates PurgEye® 100

The handheld device now features a metal housing and readings are from atmospheric oxygen level (20.94%), down to 100 ppm (0.01%) of oxygen.

Miller Electric Unveils the Reimagined Dynasty® TIG Welder

The TIG welder synonymous with precision has been reimagined for operators’ pursuit of perfection.

Embrace Digitization and Automation in the Welding Process

Take your welding operation to the next level by undertaking the first steps toward incorporating the automation journey in your shop.

Best Practices for Cutting Wheel Safety With a Variety of Wheel Diameters

Cutting wheels are an important component in metal fabrication. Place an emphasis on following best practices regarding the various diameters of cutting wheels.