Welding

Filter by Process Zone:

Premium Tungsten Electrodes

These 2 percent lanthanated tungsten electrodes from Weldcraft provide similar characteristics as the 1.5 percent lanthanated tungsten electrode, but with improved arc starting and stability, and less tip erosion. They are also a good substitute for 2 percent thoriated tungsten electrodes.

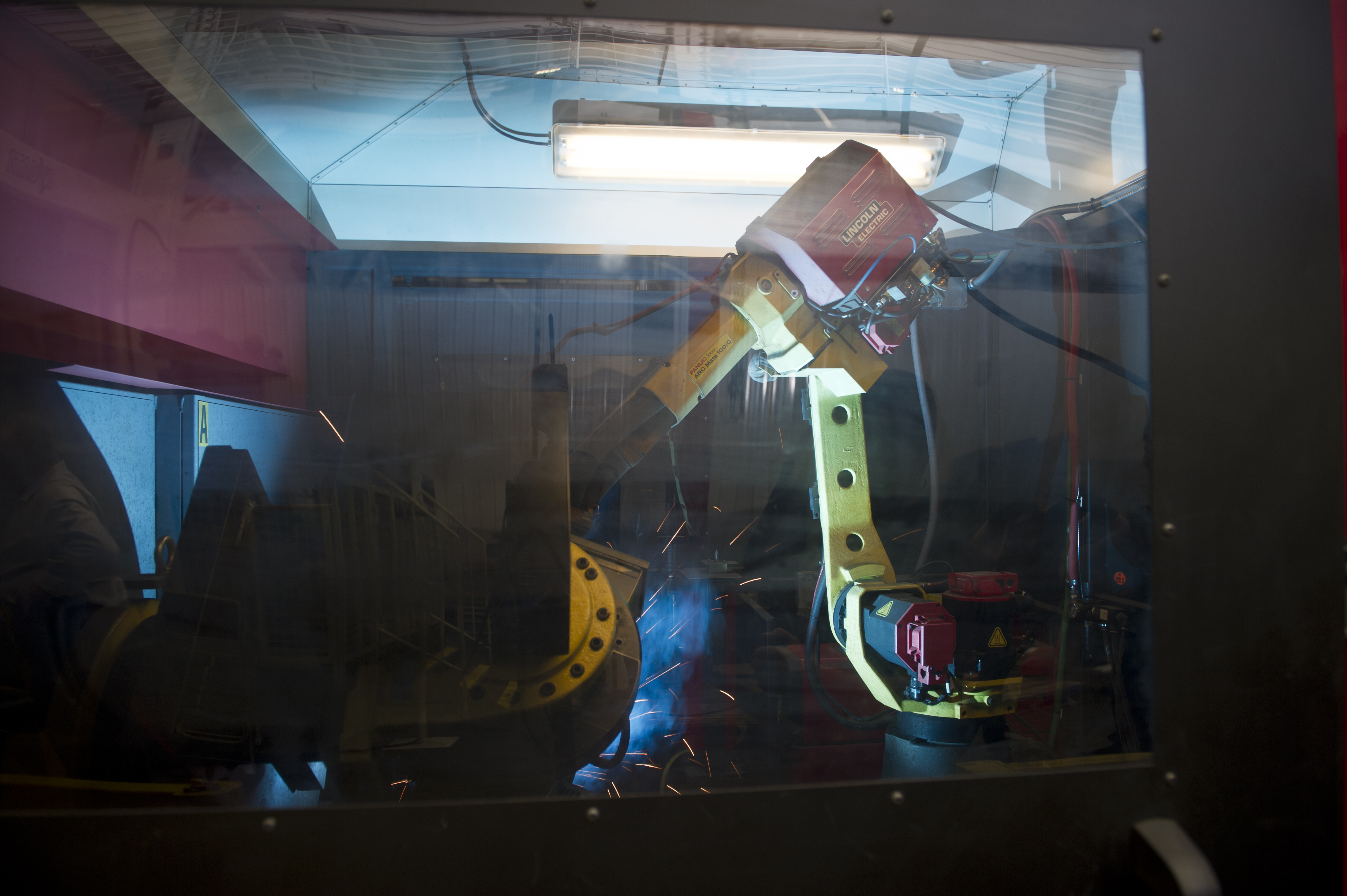

Automated Welding Increases Productivity

The Franklin plant of mining equipment manufacturer Joy Mining increased productivity and reduced costs in their bit block assembly by converting to automated welding systems from Lincoln Electric.

A Call to Action: The Need to Reform Secondary Education

Parents, schools and private industry can play a key role in better equipping our students for life after school and the full pursuit of the American dream. Nick Peterson of Miller Electric discusses the need to reform the way we think of secondary education and the path it leads to for our children and students.

Finishing Touch: Integrated Plasma Cutting

As the next natural progression in the evolution of mechanized plasma cutting, Jim Colt of Hypertherm explains how many shops are changing the roles of their programmers and the operators by switching to integrated CNC plasma cutting systems that draw more expertise from the CAM database to achieve cut consistency, increased productivity and lower cutting costs.

Welding with Robot Vision

Weld fixtures not repeatable? Inconsistent weld joints? Robots can now automatically adapt to solve these issues and more. Heath Suraba of Lincoln Electric shares some tips on how to see the best return from your vision investment.

Minimize Downtime with the Right Filler Metal Package

Delivering the right size and style of filler metal packaging on a timely basis contributes meaningfully to overall efficiency. Tim Hensley of Hobart Brothers explains how to assess your current filler metal usage to determine if you have the most appropriate size to support your production goals.

How to Determine the Diffusible Hydrogen of Mild Steel Weld Filler Material

To avoid hydrogen-induced cracking, the hydrogen level in the welding filler material must be restricted to a certain maximum level. What exactly is the method for measuring the hydrogen content of a carbon steel weld filler material?

Welding Heroes Announced by Miller Electric

Three welders have been voted as everyday welding heroes, including a 70-year-old grandmother, a contractor keeping the military fleet safe in Afghanistan and a former corporate manager who chose to become a welder.

CRC-Evans Has New Sales Direction in North and South America

The welding company hires a new sales director for North and South America that is charged with leading and growing all sales operations and organizations in these regions.

Requesting the Appropriate Level of Weld Testing for Special Order Filler Materials

Welding filler metal certification, documentation and accountability is frequently a step of the nuclear pressure vessel fabrication and military shipbuilding process. Regis Geisler of Lincoln Electric explains how to select the appropriate weld testing requirements to verify quality and attest that the products being supplied meet the constituents of the required specification.

A World of Fixturing Opportunities

The use of modular fixturing for welding is a different way of doing business, but once you get started, you will wonder how you ever got along without a system. Robert Ellig of Bluco Corporation explains why.

Next Steps in Welding Automation: Eliminating Variability and Beyond

American manufacturers are looking to drive out variability, push down costs and speed-up changeovers to better compete with overseas companies. Brian Doyle of Miller Welding Automation explores how welding automation and the data flow into and out of the welding cell is turning out to be a gold mine of potential for creating a competitive edge.