Welding

Filter by Process Zone:

Filtration System for Weld Fume Control

The Circulator™ from Lincoln Electric is a supplement to an existing source extraction system that is ideal for small shops that have overhead cranes, large amounts of infrastructure, or other obstructions for ductwork and offers an economical alternative to a push-pull system.

Lincoln Electric Dedicates 443 Ft Wind Tower

The welding OEM demonstrates its commitment to renewable energy by constructing a $5.9 million 2.5 MW wind tower at its world headquarters in Cleveland, OH, that will generate up to 10 percent of the energy used for its main plant and save up to $500,000 a year in energy costs.

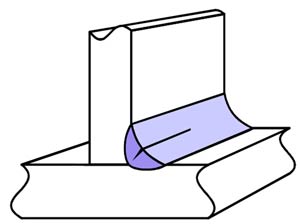

Troubleshooting the Wire Feed System

Accurately troubleshooting problems with the delivery of the welding wire to the weld pool and the current to the wire when they arise or, better yet, avoiding them before they arise, is crucial to maximizing the benefits that these processes offer.

ADVANCES IN ROBOTIC WELDING

The next generation of innovation and advances in industrial robot technology promise to increase your productivity in arc welding and other multipurpose applications.

Lincoln Electric Becomes First Welding Equipment Manufacturer to Add Tag Codes

Company implements mobile 2D technology that aids consumers in the re-sale distributor showroom with product selection and customers in the post-sale environment with operational tips and support resources.

THE TOP 10 MISTAKES IN RUNNING A WELDING OPERATION . . . AND SIMPLE WAYS TO SOLVE THEM

With equipment, weld procedures, filler metals, consumables and so many factors to monitor, it is inevitable that mistakes will occur in welding. But they don’t have to happen. Bernard, Hobart Brothers and Miller Electric review the most common mistakes that occur . . . and recommend how to solve them.

SHORTEN THE CALENDAR, SHRINK THE GLOBE

Robotic welding integrator Genesis Systems uses scalable, flexible DELMIA Robotics 3D digital manufacturing technology to get their systems to the build phase much quicker than their competitors, eliminating a huge amount of retool time, saving up to 30 percent in tool design and reducing design changes by 65 percent.

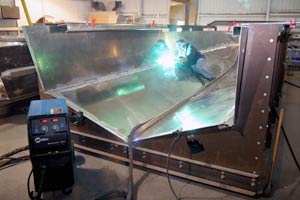

ROBOTIC SUBMERGED ARC WELDING IN POWER GENERATION FABRICATION

A welding robot typically uses a solid or metal cored electrode. Submerged arc welding (SAW) is an exception. Jeff Nadzam of Lincoln Electric explores how this highly efficient welding process is being embraced by East End Welding to deliver sound weld deposits that are lower in hydrogen, fuse well with parent materials, and create exceptional finished weld mechanical properties.

WELDING IN THE ENERGY SECTOR: CAN A PROCESS CHANGE HELP MEET INCREASING DEMANDS?

As the demands for energy continue to increase worldwide, fabricators serving this industry will be challenged to remain competitive by changing from the stick welding process to a gas-shielded flux-cored welding process. Tim Hensley of Hobart Brothers explains why they must carefully assess their quality needs and available labor or training ability before making this sort of switch.

USING 1 PERCENT NICKEL ELECTRODES FOR HIGHLY RESTRAINED WELDS, HIGHLY HARDENABLE STEELS

Circumstances exist in which the selection of low-hydrogen, mild steel electrodes such as ER70S-6 solid wire or E7018 stick electrode is not enough to prevent weld cracking. Regis Geisler of Lincoln Electric explores the reasons for this and offer possible alternatives to these filler materials.

ESAB Opening Another SC Plant to Manufacture Welding Wire

The new 250,000 sq ft state-of-the-art facility in Union County will employ more than 100 employees to manufacture MIG and sub arc welding wire.

Weiler Supports Welding Training for Returning Veterans

Manufacturer donates wire brushes, grinding wheels, hand brushes and tools to a veterans training program run by the United Association of Journeymen and Apprentices of the Plumbing and Pipe Fitting Industry (UA).