Welding

Filter by Process Zone:

Portable and Easily Adaptable Welding-Automation Solution

Lincoln Electric’s Fab-Pak Cobot Cart enables small- and medium-sized fabricators to justify investing in automation by providing a mobile, easy-to-program, and safe robotic welding solution.

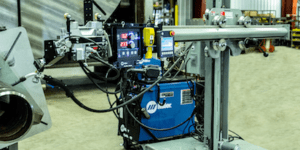

Space-Saving Automated Welding Package for Pipe Fabricators

Koike Aronson Ransome’s pipe-welding package incorporates the Cricket-I manipulator. Providing 20-IPM lift speed and 150-pound load capacity, the manipulator ensures productivity increases without sacrificing floor space.

6-Axis Welding Cobots Provide Maximum Flexibility

Fanuc adds 15- and 33-pound-payload welding cobots to the ARC Mate product line. The arc welding cobots’ easy-to-program interface supports both simple and complex applications using advanced features.

Pre-Engineered Cell Eases Transition to Automated Welding

ESAB and Yaskawa have partnered to offer small-to-medium-sized manufacturers and fabricators a pre-engineered welding cell that’s easy to set up and operate: the XCellerator.

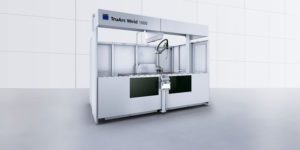

Bystronic Enters Automated Welding Market

Bystronic is selling three robotic welding options – Micro Cell, Compact Cell and Compact System – in the U.S. They’re configured by the German manufacturer Cloos Robotic Welding, which handles installation, training, and service.

Two-Arm Cobot Doubles Efficiency Without Sacrificing Safety

Even though they have two arms, Kawasaki Robotics’ duAro cobots fit into a single-person space while providing enough room for an employee to safely work alongside. Two models provide 8.8- and 13-pound payloads.

Three Updated Cobot Models Offer Greater Connectivity

The “A” in Hanwha’s HCR-3A, HCR-5A, and HCR-12A stands for “advanced.” Three cobot models improve on their predecessors by offering customizable solution packages that incorporate artificial intelligence and mobility technologies.

Design the Ideal Floor Layout for Cobotic Production and/or Assembly

Delmia Robotics’ software from Dassault Systemes maximizes automation initiatives by enabling manufacturers to design and virtually test a drilling-and-riveting, arc welding, spot welding, and/or material handling line before rolling it out.

When (and How) to Automate Sheet Metal Welding

Cobotic welding systems occupy the gap between fast and heavy industrial robots and manual welding. They also challenge the paradigm that welding automation is strictly a high-volume game.

How to Become a Multipass Welding Master

Multipass welds are often required in pipeline, ship, heavy-duty structural and pressure vessel construction. Selecting the proper abrasives and cleaning properly between each pass can help optimize results, saving the operation time and money.

Maximize Your Investment in a Welding Cobot

A collaborative robot (cobot) welds more efficiently, more consistently, and has a longer reach than its human counterparts. Here’s what to consider as you shop for a model that will boost your operation’s throughput and quality.

Videos Explain Welding Careers, In Digestible Segments

American Welding Society has introduced “AWS ARCademy,” a series designed to ‘make a positive impact on up-and-coming welders’ without overwhelming viewers with too much, too soon. New additions will continue to be added, giving students and other welding-wannabe’s a ‘crash course’ in welding basics.