Welding

Filter by Process Zone:

Water-Cooled MIG Guns For High-Amperage Applications

Three Tweco-brand welding guns from ESAB offer comfortable high-performance operation when working with large-diameter cored, solid, and aluminum wire and long-reach applications.

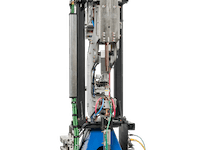

High-Speed Fastener Welding System

CenterLine introduces two SoftMount inverted-nut gun configurations for a high-speed fastener welding system that streamlines the process from operator load to finished part, providing higher throughput than standard welding solutions.

Combination Torch and Cutting System Keeps Operators Safe

ESAB’s Victor brand introduces the Medalist Classic Outfit for oxy-fuel cutting and welding. Its handle is time-tested for safety, and its G350 regulator lets operators use more gas in the cylinder without sacrificing cutting or welding performance.

Welding’s Digital Transformations, Lucrative Occupations

Deemed essential, welding and the related fabricating and metalworking trades weathered the COVID-19 disruption better than other industries, says American Welding Society Executive Director Gary Konarska II. Demand for skilled tradespeople remains high.

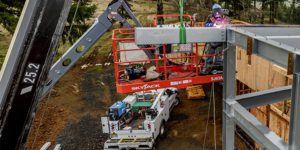

Three Ways to Cut Field Welding Costs

Walking back and forth to a vehicle to tweak an engine-driven welder/generator’s control panel takes time. Remote control devices increase productivity by putting the ability to make changes in the palm of the operator’s hand.

App Helps Avoid Welding Failures in the Field

Lincoln Electric’s NEXTime preventative maintenance app for Ranger welder/generators monitors critical functions to ensure field workers are working instead of troubleshooting productivity-sapping machine-operation issues.

Weld Purging with Preheat

Huntingdon Fusion Techniques HFT’s HotPurge minimizes the potential for cracking when welding the high-strength steel pipes used in power generation projects. The inflatable purging system is reusable.

Four Tools for Even Better Robotic Welding

Fronius increases seam quality without slowing cycle time with robotic assistance systems by making the wire electrode a sensor as well as filler metal. This eliminates the time and expense of maintaining sensor hardware and doesn’t restrict component accessibility.

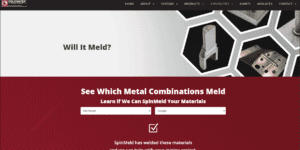

Will These Two Materials Safely Join?

Coldwater Machine’s free “Will it Meld” calculator enables manufacturers to easily determine if two dissimilar materials can be joined using the company’s SpinMeld rotary friction welding systems.

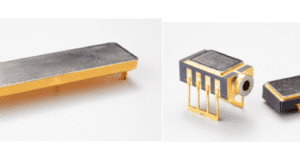

Hermetic Seam Sealing Enables Reliable Welds and Protects Electronic Devices from Harsh Environments

A primer on the two processes – parallel gap resistance seam welding or opposed electrode projection resistance welding – you can use to win customers in the highly demanding aerospace, industrial 5G commercial communications, medical device, and military electronic industries.