Welding

Filter by Process Zone:

New Sales Manager at ABICOR BINZEL

Tanner Skalla handles sales in their Rocky Mountain region.

Harris Becomes Distributor for Worthington

They handle exclusive wholesale distribution of air-fuel equipment in the U.S., also with distribution of gas cylinders.

Intelligent Positioning

Lowering the cost on shielding gas and consumables has little effect on the bottom line, but using the proper positioner to increase manufacturing and assembly efficiency can result in a significant cost savings and profit.

Top Problems with MIG Welding Consumables . . . and How to Fix Them

Take a close look at the impact of welding consumables on your overall operation, not just the purchase price. Here are some key tips on how to properly select, install and maintain consumables and troubleshoot problems when they arise – and, better yet, how to prevent them in the first place.

Added Value: The Importance of Aftermarket Care

You’ve covered every detail in upfront costs and factory floorspace, but what about technical support and service after production starts? Whether buying one robot or hundreds, having access to diverse support services to ensure peak robot performance is vital to maximizing your return on investment. Here’s why.

Five Best Practices for Multi-Material Welding in Manufacturing

To stay competitive, more shops face the challenges of welding many different types of materials. To reduce setup times and help their operators produce high-quality welds, they must move beyond basic options and invest in advanced capabilities that can have a big impact on the bottom line.

Weld Nut Sensors Increase Process Reliability

An economical alternative to more expensive optical or vision-based systems, IP67-rated weld nut sensors from Turck reliably detect the presence or absence of a nut welded to sheet metal to ensure efficient and accurate production in welding applications.

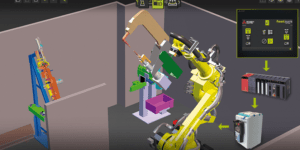

Using a 3D Virtual Environment to Reduce Downtime

Using IoT-based technology to connect robots, controllers and other real hardware to a 3D virtual environment, FASTSUITE simulation from CENIT debugs robot motion faster than ever – before downloading to actual equipment – increasing precision and efficiency to slash downtime on the shop floor

Cloud-Based Gas Detection for Hot Work Operations

With the entire iNet gas detection infrastructure from Industrial Scientific now operating through Amazon Web Services, fabrication and welding shops can quickly and easily access critical data they need online to monitor operations, prevent downtime, and save lives.

New ABB Robotics Education Affiliate

Motlow State Community College is new member of the program.

Boostweld Wins Trademark for Technology

It covers their patented GMAW gas flow technology.

Weld Fume Control

These weld fume extraction and filtration systems can effectively protect operators and nearby workers and reduce their health risks from fumes, dust and other contaminants.