Welding

Filter by Process Zone:

Lincoln Electric Launches New Education Website

This new site consolidates education products and services into one web presence.

Tregaskiss Enters Distribution Agreement with DINSE

Tregaskiss by DINSE CWD and TWD Robotic Water-Cooled MIG Guns will be available in the United States, Canada and Mexico for conventional and through-arm robotic welding systems.

Connected Metal Fabrication Systems

Using the TruConnect approach to custom manufacture a part, innovative fabricating machinery, automation systems and support technologies from TRUMPF work together to connect information and processes like never before.

A Perfect Fit for Automation: One Platform, Endless Possibilities

Kawasaki Robotics features FASTSUITE Edition 2 software from CENIT for the efficient development, reliable programming and effective optimization of their robot cells, special machines and integrated manufacturing cells that can be customized for any production environment.

Auto Height Control for Welding, Plasma Cutting and Plasma Gouging

Automatic Height Control for welding, plasma cutting and plasma gouging from Bug-O Systems utilizes arc sensing to automatically control the height of the torch from the workpiece to maintain proper arc length and provide proper and consistent weld or cut quality.

Live Welding and Gun Repair/Maintenance Demonstrations

Bernard and Tregaskiss will showcase their welding guns and consumables and demonstrate how to repair, maintain and install option changes to Bernard BTB Semi-Automatic Air-Cooled MIG Guns to illustrate the ease of maintenance or modification.

Online Marketplace Provides Suppliers with Actionable Marketing Data

MFG.com debuts the redesigned ShopIQ that offers manufacturers more tools and techniques to assist job wins and customer development.

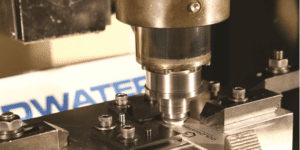

Coldwater Machine Announces Plant Expansion

The 27,500 sq ft expansion will double their build area with the addition of three new bays dedicated to assembling automated systems.

Factory Automation and Tool and Die Systems

DT Engineering builds factory automation systems, tool and die systems, and designs and produces stamping dies, including Class A/B dies, draw dies, single hit dies, trim dies, transfer dies, form dies, progressive dies and cam dies.

Weld Dissimilar Materials and Eliminate Post-Weld Inspection Processing

The automated SpinMeld friction spin welding system from Coldwater Machine is a very fast solid-state joining technology for steels, aluminum, cast or sintered metals, carbide materials, magnesium, nickel, molybdenum, and other exotic materials that normally may not be welded using other methods.

How to Manage MIG Guns and Consumables for Multiple Applications

Want to become more competitive, increase your productivity and reduce costs – all with less labor to support the efforts? Here are five tips to help you streamline the MIG guns and consumables used across the multiple applications in your shop.

Welding Game Changers for Productivity and Efficiency

Is the jobsite challenging your older equipment and costing you time and money? By switching to some of the new time-saving systems that are now available, you can save money while also improving your productivity, quality and jobsite safety.