Wire EDM Machines

Filter by Process Zone:

Mold Craft Adds to Sinker Department

Mold Craft added the Sodick AG40L to their shop and has found that the accuracy and precision is unbeatable.

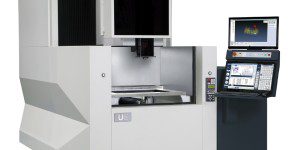

Next-Generation Wire EDM Addresses Skilled Labor Shortage

Using HyperCut technology and Hyper-i control, U3 and U6 wire EDMs from Makino enable novice operators to program and produce leading-edge part finishes in the most complex feature geometries.

Sodick Announces Regional Manager

Sodick has brought on board a new regional manager, Todd Romeiser.

Wire EDMs Offer Versatility and Low Operating Cost

Makino’s user-friendly U3 and U6 Wire EDMs offer next-generation process versatility and low operating cost for optimum performance and improved profitability.

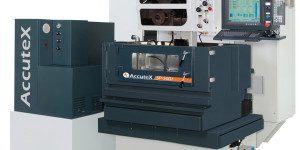

Wire EDM Provides Exceptional Part Finish for Aerospace, Medical Applications

The AccuteX EDM “SP-500i” 5-Axis CNC Wire EDM from Absolute Machine Tools is built for rigidity with a Meehanite cast honeycomb base, highly-ribbed column that is mounted with oversized UVZ axis and reinforced lower arm for added stiffness. All castings are stabilized and subjected to rigorous testing to insure maximum strength, high precision, and durability.

Sodick Showcases Wire EDM Linear Motor Drive Technology

The Smart Technology Event conducted live demonstrations of a new range of rigid linear motor driven Wire EDM machines and other high speed machine tools that offer small to mid-size shops a competitive advantage through improved part accuracy, repeatability, speed and acceleration.

GF AgieCharmilles Unveils Streamlined New Website

GFAC debuted a completely new U.S. website that offers increased user-friendliness and reflects the visual identity of parent company Georg Fischer.

Mazak Certifies Kennametal as Newest VIP Partner

Kennametal will collaborate with the firm on R&D and integration efforts to create more innovative products and turnkey processes for the U.S. manufacturing market.

Wire EDM Machines

A CNC wire electrical discharge machining (EDM) tool taper cuts or shapes conductive materials using a thin electrode that follows a precisely programmed path. A gap between the wire and the workpiece ensures no distortion in the path of the…

Wire Changing EDM Proves Big in Micro Tooling Production

As consumer products continue to shrink in size, die shops such as Scenic Tool and Stamping face the challenge of developing highly intricate tooling for stamping the tiny components that make up miniature merchandise. As a result, an increasing number of these shops are incorporating high-precision wire EDMs like the Cut 2000 from GF AgieCharmilles that provide automatic wire-changing capability.

uses the to easily switch wires of different sizes and materials.

Hypercut Wire EDM Technologies Increase Profitability

HyperCut technology from Makino reduces cost per part by producing 3µm Rz surface finishes, reducing cycle times by 20 percent and wire consumption by 14 percent.

Revolutionary Cylindrical Drive Motor Expands Wire EDM Capabiliites

The Mitsubishi MV Series Wire EDM from MC Machinery Systems reflects a major step forward in wire EDM technology by using cylindrical shape technology to minimize heat output and keep out shop dust.