Wire EDM Machines

Filter by Process Zone:

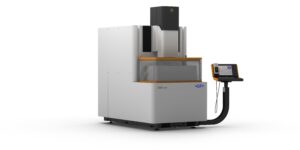

Die-Sinking EDM with Part- and Electrode-Changing Robot

The AgieCharmilles FORM X 400 with System 3R WorkPartner 1+ from GF Machining Solutions speeds output by bringing all production technologies together in one process chain. Users also benefit from the updated control interface’s advanced levels of logic, speed, and safety.

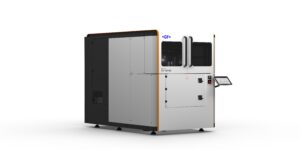

Automation-Ready EDM Speeds Up Additive Part Separation While Preserving Part Integrity

By blending horizontal wire orientation, a rotary axis, and an integrated basket to catch separated parts, the AgieCharmilles CUT AM 500 from GF Machining Solutions facilitates additive manufacturing (AM). The combination of features supports the part, allows for easy part handling, prevents part damage, and offers full automation readiness.

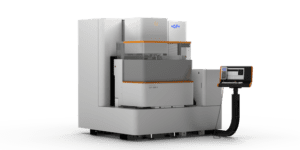

Spark Track Technology Prevents Wire Breakage for Easy, Stable EDM Processes

Two integrated features enable the AgieCharmilles CUT 2000 X wire EDM to provide unmatched accuracy and flexibility: GF Machining Solutions’ Intelligent Spark Protection System (ISPS) averts wire breakage by automatically unifying discharge distribution and Integrated Vision Unit (IVU) Advance automatically corrects machining errors.

Beaumont Machine Offers Value-Priced EDM

Fast-hole electrical discharge machine (EDM) supplier offers a new CNC wire-cut machine, the S-EW3, at an affordable price. E-learning training software enhances user’s experience.

Hybrid-Coated EDM Wire Increases Productivity 15% to 20%

More than 50% of Clippard’s pneumatic valve and cylinder production is done via wire EDM. When Global Innovative Products (GIP) needed real-world validation of its testing on Plasma, a gamma-phase intermetallic zinc alloy-coated wire with brass core, Clippard successfully used the wire to produce tooling.

How EDM Technology Is Adapting to the Realities of the Modern Workforce

The difference between a skilled operator and an inexperienced one is night and day. Machine builders are helping manufacturers remain productive and profitable by deploying technologies that close the skills gap between dedicated operators with extensive knowledge of just one process and today’s jack of all trades.

GF Machining Solutions Opens New Headquarters

They open their new Innovation and Production Center in Biel, Switzerland.

Leadership Changes at GF Machining Solutions

Scott Fosdick is now head of global sales and marketing; Phil Hauser becomes president of the North and Central America market region.

Changing Distributorship at GF Machining Solutions

They are expanding channels and regional sales throughout North America.

Spark New Life into Complex Machining

Optimized, faster cutting speeds. Reliable accuracy. Easy programming of advanced control capabilities. Lower maintenance and reduced operating costs. And all at a reasonable price. Welcome to the newest EDM systems.

Advanced EDM for the Most Difficult Jobs

Innovative FANUC CiB-Series wire EDMs and Ocean EDM Drills from Methods Machine Tools cost-effectively machine complex parts with increased accuracy, speed, and throughput

A Simple Solution for Complicated Production

For efficient, reliable cutting of complex geometries, W-EDM wire sinkers, S-EDM and Z-EDM sinker eroding machines from KAAST come complete with water bath and can copy, turn, flip, scale, and rotate the working material to create a steady stream of tools/dies.