Wire Feeders

Filter by Process Zone:

Auto TIG: Automating TIG Welding is Becoming More Feasible

Automated TIG welding is something you don’t hear much about in the industry – especially in comparison to automated MIG welding – but interest is growing.

Cutting-edge Welding Solutions to be Showcased at FABTECH 2023

Miller Electric Mfg. brings the “Power of Blue” to the show floor, where attendees can try out the newest technologies live and discover products to help evaluate your operations.

Airgas to Feature Advanced Fabrication Innovations at FABTECH 2023

Customers will be presented with methods to drive efficiencies and gain competitive advantages through Airgas’ innovations in automation, additive manufacturing, cutting, welding, safety and service.

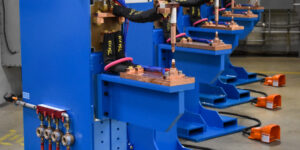

T.J. Snow: One-Spot-Shop for Resistance Welding

As the company celebrates its 60th year in business, it is excited about the future of its products and its place in serving the metalworking industry.

MIG Welding FAQ: Best Practices for MIG Success

Tips to troubleshooting a few common MIG welding issues will help operations improve productivity and quality, as well as reduce downtime.

Five Tips for Implementing a Robotic Welding Cell

Get the most from your robotic welding investment through careful planning and continued monitoring.

New Welding Systems Deliver Next-Level Productivity, Cost Savings and Power

Miller Electric’s power sources and wire feeder are designed for structural fabrication, steel erection and shipbuilding.

ESAB’s RobustFeed Pro Connects to Competitive Welders

RobustFeed Pro is part of the RobustFeed wire feeders and Heavy Industrial Warrior® and Aristo® power sources, covering the needs of nearly all shops.

ESAB Launches Demo Box Program for Its Heavy Industrial Welding Systems

Demo Box contains everything needed to start welding: power source, feeder, wire, cables, guns, PPE and extra contact tips.

Space-Saving Compact Air Filtration System

Lincoln Electric’s Prism Compact fume-extraction system for welding and cutting applications incorporates the Prism line’s vertical filter technology. Available in indoor and outdoor configurations, the short unit fits efficiently into smaller spaces.

Heavy-Duty MIG Guns Perform at 100% Duty Cycle

Four Magnum PRO Curve HDE semiautomatic welding guns from Lincoln Electric provide the best of both worlds: They deliver the highest duty cycle in their class and maximize operator comfort with a new ergonomic design.

Engine-Driven Welder Enables Simultaneous Welds

Lincoln Electric’s Dual Maverick 200/200X is two welders powered by one diesel engine with two outputs, allowing two or more welders to work at the same time. Output remains steady even during arc stops and starts in dual mode.