Column

Filter by Process Zone:

BECOMING FAMILIAR WITH THE X-FACTOR

Ideal for use when welding boilers, process piping, heat exchangers and other applications subject to high service temperatures for long periods of time, Tim Hensley of Hobart Brothers introduces a formula that helps determine a weld’s resistance to the brittleness that occurs when the weld is slowly cooled through a certain temperature range.

GOING FOR GREEN LIGHT: REDUCING LASER SETUP TIMES TO KEEP THE BEAM ON

Green light time is the way to make money operating a machine tool, and it never hurts to go back and review some basic principles for improving productivity in a laser fabricating process. With an eye toward keeping that light on longer, Tom Bailey of Trumpf looks at a few simple strategies that can pay off.

PULLING IT ALL TOGETHER

Approaching Safety Holistically (Part Two): While safety training is important, Phil La Duke of Rockford Greene explains how the real payoff for investing in training comes from monies spent on imparting the most basic skills workers will need to do their jobs.

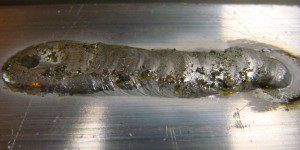

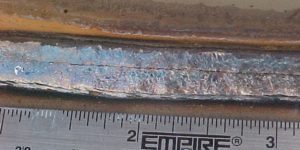

CORROSION OF PIPE WELDS MADE WITH METAL-CORE WIRE

Regis Geisler of Lincoln Electric analyzes the recent occurrence of this situation at a fabrication site, then recommends some remedies for mitigating the effects.

ENERGY EFFICIENCY PLUS FULL DATA TRACKING – A CNC CHRISTMAS PRESENT!

Randy Pearson of Siemens Industry shows how today’s CNC not only puts a greater degree of energy efficiency at your fingertip, it can also provide you more usable data for running your entire shop or machining department . . . yes, Virginia, there IS a Santa Claus!

Tallying True Costs

When a machine spindle goes down, much more is involved than simply the bottom-line review of a repair bill or the purchase price of a new spindle. Additional underlying costs include more than dollars. Ed Zitney of SKF Machine Tool Services examines what you can do to help save time and money when a good spindle fails.

APPROACHING SAFETY HOLISTICALLY

After a process is stable and compliant, safety should focus on worker and process capability by diverging into worker skills and equipment maintenance. Phil La Duke of Rockford Greene reveals why there is no need to spend lots of time trying to improve workplace safety through worker training and total productive maintenance when there are many other low-cost actions that can be quickly deployed.

Staying One Up: New Ways of Doing Business

It is useless to worry about whether the economy is getting better or worse. Instead, focus on out-marketing your competition. Here are several effective ways to do just that.

How to Pick the ‘Right’ Angle Abrasive

New products have expanded the right angle grinder’s use, but they have also added some complexity to the selection process to match the right product to the right material and application while meeting the criteria most important to the end user. Dave Long of Norton Abrasives shares some helpful selection tools to simplify the process.

10 Common TIG Problems and Solutions

Here are some descriptions of common TIG mistakes and basic tips on how to prevent these errors from happening.

Financial Justification: Achieving a Two-Year Payback with Robotic Welding

Deciding whether to convert manual or semiautomatic arc welding stations over to robotic welding is typically driven by the payback or return on investment achieved through labor savings. But Geoff Lipnevicius of Lincoln Electric explains that labor savings do not comprise the total anticipated savings and shows how they are generated from a variety of other process-related areas.

Basic Tips for Understanding (and Preventing) Common Types of Weld Cracking

The best defense against weld cracking is to understand its causes and solutions. And he shows why the best place to start is by understanding hot cracking and cold cracking.