Column

Filter by Process Zone:

Equipment Lease Versus Loan: Which Is Right for Your Shop?

Many machine shop owners are planning to make capital investments within the next year, which includes machinery. There are a few questions you should consult with your lender when dceciding if it’s better to lease or take out a loan.

Up Your Game with Reliable and Safe Cleaning and Lubrication Products

Fabricators can attain spotless and unsoiled parts and machinery in an environmentally responsible way.

Five Ways to Improve ROI with the Right Maintenance Products

Reduce machine downtime and improve efficiencies by using products designed to tackle the most demanding maintenance challenges.

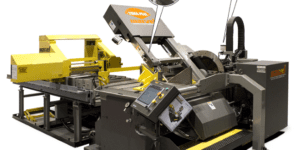

Have You Considered a Robot or Cobot for Your Plant?

Machine tending robots have revolutionized manufacturing and offer multiple mounting options, which allow you to save floor space, increase throughput and overcome labor issues, among other benefits.

Monitoring the Process

Automated measurements of workpieces in machines are progressively more important in today’s manufacturing processes, resulting in shorter production times and fewer interruptions. What’s more, there is more confidence when it comes to the measurement process.

Touch Probes as a Metrology Tool for In-Process Inspection

There are three important features to look for when deciding on a touch probe for in-process use.

Tool Management Systems Aren’t Just for Managing Tools Anymore

Today’s tool presetters capture all the data associated with a tool in order to expediate setup in the tool crib, reduce scrap and waste, and even track what’s happening on the shop floor. Presetters act as a communication/data hub, capable of integrating with CAM software.

Metalworking Fluids: Less Is More

A targeted and calibrated approach to lubrication ensures fluids arrive exactly where they need to be, when they need to be there, and in the correct amount, ensuring metalworkers are confident in their ability to make good parts.

Uniting Press and Automation

You will meet or exceed expectations by partnering with a press manufacturer that is an authorized systems integrator, and truly understands the scope of your goals by adding a fully integrated automation solution.

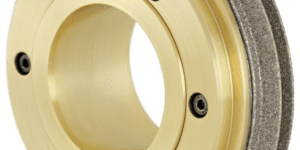

Set Your Gears in Motion

Innovative tools and equipment are available to support today’s gear manufacturing processes and keep the wheels of production spinning.

Laser Welding Made Even Easier

Laser welding allows your team to produce narrow deep welds, commonly used in high volume applications, at fast speeds.

How Automotive Robotics Paved the Way for Modern Automation

Demand for automation continues to escalate as companies search for ways to optimize operations — at this time only a small percentage of factory work is automated. Factory automation has come a long way — where to next?