Column

Filter by Process Zone:

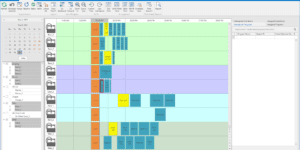

Data Driven Production, from Order Entry to Execution

Break data into small segments in order to develop good data, resulting in better solutions.

Sneak Preview Fabtech 2021

Back in action! Fabtech returns to Chicago.

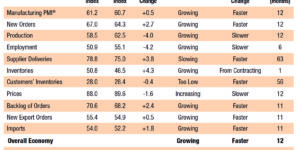

Manufacturing’s Optimistic Outlook Continues to Soar

As the nation’s economy reopens, the manufacturing sector will be a major player on the road to prosperity. Buckle up.

Five Things You Need to Know about Smart Manufacturing

Leverage machine learning to make better decisions in real time.

The “Smart Factory Five” for Robotic Automation

There are key areas manufacturers must be mindful of when creating a completely integrated smart factory, especially where robotic automation is concerned.

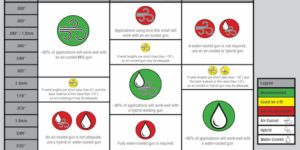

Consistent Consumables

Take a peek into the latest product developments regarding consumables.

Best Practices for Welding Wire Spool Selection and Setup

Deciding on the appropriate welding wire spool for your job results in productivity, efficiency and profitability.

Improve Productivity by Preventing Five Common Welding Problems

Common problems in the weld cell can be costly and time consuming. Optimize your setup and efficiency so troubleshooting goes much faster when issues develop.

Smart Stuff: Driven by Data, Machines and Tools Almost Think for Themselves

Bill Berutti, CEO at Plex Systems, sums up the status of manufacturing and digitization: “Smart manufacturing isn’t something that will happen years down the road … it’s real, it’s imperative and it’s happening now.”

Abrasives Are Not All Created Equal

Many shops hesitate to incorporate abrasive finishing tools in CNC machines for fear of clogging coolant lines and damaging slides and bearings. However, finishing tools generate very little grit.

5 Common Questions About Implementing a Robotic Welding System

Proper cable and consumables selection and tool center point (TCP) control play go a long way toward improving quality and optimizing overall equipment effectiveness (OEE). Establish a thorough pre-implementation plan and monitor key issues to get the most of your investment.

Appearances Can Be…Achieving!

Everyone’s ready for a fresh start this year, but one company isn’t leaving 2021 outcomes to chance. A dynamic new marketing approach for 120-year-old Jarvis Cutting Tools included a logo redesign, a bold undertaking led by an industry outsider.