Column

Filter by Process Zone:

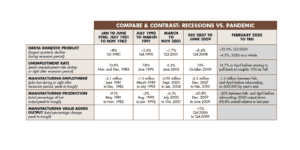

Partnering for a New and Stronger Tomorrow

When the pandemic hit, many companies used the downtime to make data-driven automation, process, and employee training improvements. As global supply chains reconfigure, those investments are paying off.

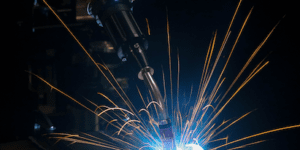

How to Choose the Right Type of Contact Tip for Your Robotic Welding Cell

Contact tips may be tiny, but using the wrong type or replacing them too soon can have a huge impact on productivity. Here’s what to consider to improve results and save money by properly matching tip type to application.

Advanced-Grain Nonwoven Belt Improves Stainless Steel Finishing Process

Finding people who are willing and able to press metal against an abrasive belt all day long can be challenging. Nonwoven belts make the job more appealing by increasing productivity without increasing effort.

Growing CNC Services With 5-Axis Milling

McAfee Tool & Die is successful because it’s always ready to take a leap of faith with new technology. When owner Gary McAfee bought a 5-axis machine, he realized it was time to update the shop’s CAD/CAM software.

What to Know About Stress Relieving After Welding

With the proper process, oil and gas industries that require components to maintain corrosion or cracking resistance can have peace of mind that elevated service temperatures or multiple repair cycles won’t cause damage.

Comparing Methods for Welding Preheat

Heating the base metal adds time and money up front, but can save time and money by minimizing potential for weld failure. Here’s how to determine the best preheating method – convection ovens, induction, open flame, or resistance heating – for your application.

Give It Up for an All-Around Value-Maker, Efficiency-Builder: Press Brakes

What can’t they do? An MC Machinery spokesman demonstrates how press brakes and press brake tools are so multifunctional and adaptable, manufacturers can creatively use them in applications beyond sheet metal and stamping dies.

Programming a Robot Doesn’t Have to be a Dark Art

As production goals change in a post-pandemic world, more manufacturers are using robots to deal with labor shortages and high-mix, low-volume (HMLV) orders. Easy-to-use tools for novice operators are enabling faster implementation on factory floors.

Solving & Evolving With An Unflappable Mindset

Modeling deeply intentional and thoughtful leadership, the CEO of a machining company equips his team mentally and digitally to muscle through myriad obstacles –– and emerge victorious for their customers and themselves.

Quality 4.0 is Achievable When Systems and Culture Merge

Nothing frustrates improvement efforts like software programs that don’t play well together. Brothers Brian and Mitch Olson made sure that didn’t happen when they launched their CNC machining shop by deploying a solution that integrates resource planning and quality management.

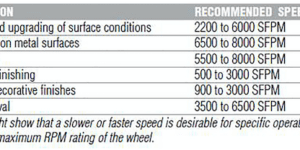

It Might Be Time to Use a Flap Disc Instead of a Standard Grinding Wheel

New technology is making the flap disc a cost-effective and equally effective alternative to grinding wheels in a variety of applications. They’re versatile, lightweight, easier to control, and convenient.

How to Solve 8 Top Problems that Undermine Profitability in Metalworking Operations

Every ounce of additional productivity rung from each step in the process adds up to significant cost savings over time. From coolant and tooling to programming and scrap management, opportunities to increase efficiency abound.