Column

Filter by Process Zone:

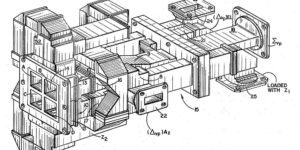

From One Hundred Parts Down to One

By combining RF design simulation, mechanical engineering and system optimization focused on additive manufacturing, this antenna maker greatly reduces the size, weight, lead times, part count and cost, with as-good or better RF performance than conventionally manufactured systems – and creates structures that simply were not possible to produce in the past.

Tips for Successful Aluminum MIG Welding Repairs

With its low melting point, the presence of an oxide layer on its surface, prone to burn-through with a difficult-to-control weld pool, aluminum can be somewhat tricky. Here are some insights that will provide you with the best course of action to take for making a repair.

Why Prospecting Fails and What To Do About It

How to engage prospects so they want to find you. It’s called Pull Prospecting.

Rebuilding American Manufacturing, One Veteran at a Time

A perfect storm: One million veterans leave the service every five years as a projected two million manufacturing jobs go unfilled in the U.S. over the next decade due to lack of skilled labor. Take a closer look at how veterans are forging new careers in metalworking through Workshops for Warriors – and how manufacturers can put skin in the game with support.

Avoid These Costly Mistakes in the Welding Operation

Looking to improve productivity and reduce costs to be more competitive? The one key to getting ahead is reducing the time spent on non-value-added activities – i.e., any time spent not welding. Here are some of the best ways to reduce downtime.

Deep Etching with a 2D Fiber Laser

Laser etching is a useful tool, but its limits as a light surface effect are apparent when a part number needs to be visible through paint or a powder coat. In these cases, deep etching can provide a simple solution – the trick is finding the right combination of hertz, laser wattage, focal diameter, and gas for your specific material.

Time to Reconsider Holding Taps with Collet Chucks

The next time you think about setting up a tapping operation with a collet chuck the same old way you always have, you may want to think again. There are now tap holders designed specifically to mitigate the load imposed on the tap by essentially absorbing synchronization error.

Metal 3D Printing for Land, Sea, Air and Space

When a submarine manufacturer saved significant time and cost by using Electron Beam Additive Manufacturing to 3D print a titanium Variable Ballast tank, the technology became the only industrial-scale metal 3D printing process with approved parts for land, sea, air, and space applications.

Better Fume Control for Large Weldments Starts at the Source

Is your weld fume solution a fan and an open window? Working on large weldments – such as heavy equipment, ships or wind turbines – makes fume capture a challenge. However, today’s manufacturers have more options for fume control than ever. The best option for manual welding of large components may be one you haven’t considered for a while: the fume gun.

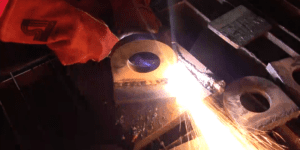

Approaching Removal Jobs from a New Angle

Efficient attachment removal has always been tricky. Without the ability to mechanically position the tool so that a closer cut can be achieved with less residual metal, workers were forced to deal with the drawbacks of traditional removal processes. But not anymore: A small alteration has made a huge impact on the attachment removal process.

Reduce Moisture-Absorption and Cracking Risks with Seamless Wires

Not every welding application requires the benefits that higher priced seamless wires provide. But when moisture must be controlled to help minimize the risk of hydrogen-induced cracking in demanding high-strength applications – and with it, costly repairs or potentially catastrophic weld failures – seamless welds are the ideal solution for the job.

How to Choose for Your Roll Former: Pre-Cut Vs. Post-Cut

Sometimes it’s equally as important to know what not to do as it is to know what to do. When it comes to investing in roll forming equipment and accessories, quality roll tooling designers must consider the possibilities for each customer.