Column

Filter by Process Zone:

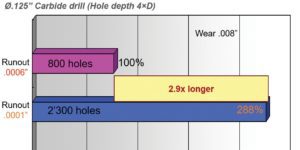

Tools, Holders and Runout: Uncover the Hidden Savings

Runout can be fickle, but finding a solution for it can pay significant dividends. Here are some insights into how much a little wobble can really increase your costs.

Millennials in Manufacturing: Recruiting, Retention and the Factory Environment

If you work in a manufacturing environment, chances are when you come to work you see lots of grey hair. According to the U.S. Department of Labor, more than half of skilled manufacturing workers are now 55 and older – and getting closer to retirement every day.

Understanding Stainless Steel Filler Metals

The properties of stainless steel offer corrosion resistance, toughness and strength, a good appearance and longer useful life. But there are some challenges when welding stainless steel. Consider these tips and best practices, including proper filler metal selection, to get the most from stainless steel welding applications.

Cutting Through the Confusion with Non-Woven Convolute Wheels

The complicated array of convolute wheels being used on the production floor can confuse operators who find it difficult to select the right one for their specific deburring or finishing job. But now a new system simplifies all of that, reducing lost time in selection and downtime due to rework, increasing cost savings through higher productivity.

The Future of Oil: The View from Right Now

Because the world as we know it is still mostly built on the trapped sunshine that is oil, the oil industry was the most consequential market of the 20th century. Guest columnist Chet Biliyok of Energy and System Technical analyzes how the industry must now step up to the challenges of this century.

Conventional Guns on Through-Arm Robotic Welding Systems: When to Make the Choice

The choice between using a through-arm MIG gun or a conventional gun is sometimes an afterthought on these systems, but there are applications where a conventional gun works better and can significantly impact efficiency, throughput and quality of the finished weld. Knowing how to choose the best option for the job up front is key.

A Warm Welcome for New Equipment

How to prepare your shop for a smooth installation that gets your new machinery up and running efficiently and as quickly as possible so it can begin generating money for your company.

A Review of Vibration and Affordable Ways to Prevent It

While the latest machine tool technology may go a long way towards eliminating vibration and chatter, adding a new one may not be realistic. Luckily, there are less disruptive options that can make positive impacts on vibration without breaking the bank.

Direct Metal Deposition Gets Drive Shafts up to Speed on Container Ships

The labor intensive, time consuming conventional casting of alloys is becoming a thing of the past as new robot-assisted laser systems take the fabrication and repair of sliding bearings to an innovative new level in the gigantic container ships that travel across the world’s seas.

How Energy Incentives on New Welding Power Sources Benefit Your Bottom Line

Considering an upgrade to your welding equipment to increase profitability and cut operating costs? Here’s how you can also take advantage of the additional benefits that energy incentives provide for an even greater impact on your bottom line.

Tips on Fine Grinding Stainless Steel

Choosing the right equipment and consumables to grind a fine finish on stainless steel can get the job done faster with less operator fatigue. Here are nine ways to create a smooth surface in some typical finishing applications.

Your Robot Colleague is Coming Out of Its Cage

Creating a future of automation that is not about man VS. machine, but man WITH machine.