Column

Filter by Process Zone:

A Look Ahead: Five Air Quality Trends to Watch in 2017 and Beyond

Modern air quality systems are smarter, more efficient and more effective than ever before. If you’re looking into a new air quality system, be sure to consider these future-focused trends.

Tips for Choosing the Right Product for Welding and Fabrication Surface Finishing

Here are some insights on how to address the varying levels of surface finishing requirements that depend on industry demands and the eventual end use of the finished product.

Great Expectations

This family-owned and operated machine shop explains how they found a grooving and cut-off system at a competitive price point that performed beyond their expectations by cutting their insert costs in half and tripling their tool life.

Best Practices for Success in Self-Shielded Flux-Cored Welding

This welding process offers good weldability, high deposition rates, and excellent chemical and mechanical properties for structural steel erection, bridge construction and heavy equipment repair. But it does have some challenges. Here are some tips to help address these challenges and save time, money and frustration.

Getting the Edge You Need When Beveling

Beveling is an integral part of joining components. There are many ways to create a beveled edge, and the method or tool you choose makes a big difference in completing the operation quickly, reliably and safely. To help you in this selection, let’s take a closer look the beveling process, which is still considered by many to be as much of an art as a science.

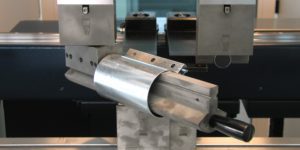

Machining Heat-Resistant Super Alloys? Hold On Tight

The chances of a tool slipping or pulling out in its holder during work is increasing as more shops opt for heat-resistant super alloys – stainless steel, Inconel, titanium and others – over aluminum. These metals are lightweight, strong and corrosive-resistant, but they are very difficult to machine. Here are some insights into tool wear in these applications that can help you select the proper holder for your work.

Keeping the Green in Green Energy Manufacturing

How clean are your manufacturing processes to build clean energy components? Here are some steps that go a long way towards improving the health and safety of workers in the clean energy industry and reducing the environmental impacts of manufacturing clean energy components.

Complexity Comes for Free

Producing metal parts in a powder bed fusion process is proving to be a game changer in the energy sector, where it generates new opportunities to produce previously impossible geometries in internal cooling channels or undercuts that are used in all sorts of heat exchangers and turbine generator systems.

The Machine Tool Goes Digital

As digital and virtual simulation optimize its mechanical, control and networking capabilities, the machine tool of the future will be redefined as a functional node in the broader network of the Internet of Things.

Welding Abrasion-Resistant Plate: Three Common Challenges and Their Solutions

Here are some tips that make it easier to avoid cracks and prevent lost time and money when welding these incredibly hard plates.

Closing the Loop: Strategies for Bending Closed Forms

With a bit of creativity and thought to overcome limitations, it is often possible to form closed profiles and other difficult parts with a standard press brake. Here are some tips on how to do it.

The Importance of Proper Welding Operator Training

To gain more business in the face of a skilled labor shortage, fabrication shops need welding operators that are familiar with a wider variety of welding processes and materials and can take on new jobs to set their shops apart. Proper operator training plays a key role in reaching these goals.