Column

Filter by Process Zone:

Analytics: The New Frontier in Manufacturing

Data analytics is a key technology that is creating new frontier for manufacturers to uncover new insights that can speed their decision-making and improve their business performance.

How to Select a Single-Source Automation Supplier

Matching the automation to the need keeps a shop competitive, which is precisely why the selection of knowledgeable and experienced suppliers is equally or potentially more important than choosing the actual equipment.

New Ways for a New Day

Advances in welding technologies and processes can help fabricators address the shortage of skilled welders, shorter project turnaround times, the need to report and document weld quality, and other critical industry challenges that are impacting their profitability. Here’s how.

Tooling Up for Large Radii: Four Methods for Forming Radius Parts

Is your shop having problems forming parts that require a large radius with a press brake? These four proven techniques can increase your part quality and eliminate scrap with minimal investment.

How to Protect Against Liability for Contractor Employee Injury

When an employee of a contractor is injured in a manufacturing plant, the owner of the plant becomes a prime target for a lawsuit. An indemnification agreement can be a shield of protection against this liability – if it is used properly.

Making Selling Easier

Ideas For Combating Complacency: Being different from others in sales means having conversations with customers, asking questions, clarifying issues and being as transparent as possible. Customers today need salespeople who are competent diagnosticians, who have developed expertise at identifying what needs to be fixed and how to go about doing it.

Make This to Print

How the technology and trends in additive manufacturing are changing the production methods of the future.

The Roadmap to 24/7 Machining

To run a manufacturing facility around the clock requires planning, the right equipment, efficient processes and the dedication to implement each step for repeatable processes. With these elements in place, a company can work toward its goal of producing perfect parts on time, no matter the customer requirement.

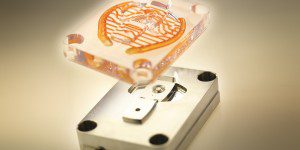

Insider Q&A: Questions Answered About Water-Cooled Robotic MIG Guns

Using either air or water to keep a robotic MIG gun cool is critical because it protects the components from damage due to radiant heat from the arc and resistive heat from the electrical components in the welding circuit. These insights will help you determine if a water-cooled gun is the best fit for your application.

Understanding Sheet Distortion During Punching

Sheet bowing is a common problem, but also predictable and therefore able to be addressed.

Closing Sales Means Making Sense to Customers

Selling is easier said than done. Cutting corners is best left to the amateurs and those who think they can talk or manipulate their way to success. It takes the entire sales process for consistent positive results.

New Weld Brushes Make Flipping Easy

Thanks to new technology that increases wire life and operator safety as the brush wears, flipping your wire brush during surface cleaning has never been easier.