Column

Filter by Process Zone:

Horizontal Machining vs. Vertical Machining: Rethinking Your Operation

If the manufacturer is able to move past the sticker price and examine the dollars spent making the part, or the cost per part, a multitude of qualities can factor into the machine tool’s return on investment. Here are some reasons why a less expensive piece of equipment is not always the obvious choice.

Next Generation Speed Governing Technology

Numerous benefits can be gained from improved fuel efficiency and reduced noise when using new welder/generators with speed-regulating technology.

A Practical Approach to Bending Length Precision

To hit those very small flange length tolerances on our prints, we need to master that material stretch. This means we need to understand not just the material, but also how the press brake tooling being used to perform the bend will change the amount of stretch and impact the size of the blank.

Equipment Purchase Agreements: Pay Now Or Pay (More) Later

You should devote almost as much attention to documenting the deal as you did conducting the bid process to cover the many things that can go wrong in the time between making the down payment and final acceptance. Here’s why.

Ten Sales Strategies For Taking Charge of 2015

It isn’t how well known salespeople are that makes the difference; it’s how much help they give that counts. When it comes to lasting results, these sales strategies can make a real difference.

Automating the “Feel” in Deburring and Edge Finishing

Quantifying and adapting the “feel” of the abrasive against the part is a critical step toward successfully automating this labor intensive offhand operation.

Making a List, Checking It Twice

Returning your machine or a program to its original condition can now be as simple as saying “big data.”

Navigating OSHA’s Hierarchy of Controls to Minimize Weld Fume

In considering which weld fume management solution is right for your shop environment, be aware that it may be necessary to implement multiple solutions from the agency’s outlines to achieve the desired exposure limits for each individual metal, metal oxide or gas found in the weld plume. Here are the steps to follow.

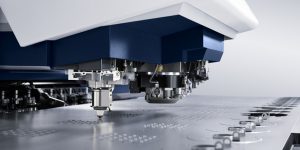

Rethinking Your Parts: Combining for a Competitive Advantage

You may discover a whole new profit method in a combination processing machine that can produce all of the geometries you need at the same cost, regardless of the number of parts required.

How to Get (Really) Good at Business Communications

It takes a near miracle to get clear, correct, and compelling written or spoken business messages across today. Whether emails, letters, memos, presentations, or reports, most create confusion, cause mistakes, and waste time. These suggestions can help you tackle the problem.

3D, Robots, Big Data and a Few Memories

Looking back at IMTS 2014, we all got a peek into the future of additive manufacturing and process chains, plus a few exciting concepts that are going to find their way into the operation of your shop very soon.

Tips for Proper Liner Installation to Help Optimize MIG Gun Performance

MIG gun consumables are often one of the most overlooked portions of the welding operation. However, choosing the right consumables, and using and maintaining them properly, can make a significant difference in gun performance and weld quality.