Column

Filter by Process Zone:

Safety in the Digital Age: Regulating Worker Use of Distracting Devices

The dangers of distraction while working have garnered a great deal of attention. Distraction increases the risk of injury, but taking the appropriate steps to reduce distraction are neither easy nor simple. Much thought must be given to the consequences, fairness, and practicality of any regulations aimed at reducing the risks associated with worker distraction.

Breaking Down Automated Bending

Here are five basic areas to evaluate when considering whether it is right to invest in an automated bending solution, and if so, which type of system to choose.

It Takes The Right Tactics To Improve Sales Performance

When salespeople use these tactics, they boast less, do more and improve their sales performance.

The Manager and Smart Machines

In the Age of Smart Machines, will humans continue to have a strong comparative advantage when it comes to inspiring the troops, empathizing with customers and developing talent? Martin Dewhurst and Paul Willmott of McKinsey & Co. share insights into the need for softer skills and technology savvy in the increasingly complex role of management.

From Producer to Partner

From product design and prototyping to metal fabrication and assembly, companies need an expert, all-in-one supply chain partner to help them take their business strategy to the next level.

Going in Forward and Reverse

The entire machining process chain can now be run in art-to-part simulation, with feedback and corrections made from end-to-end.

Fume Extraction Guns: What to Know for the Best Performance

Knowing some basic details about fume extraction guns, as well as good technique for using them, can help welders gain the best performance from this equipment.

Safety As Sustainability

The broader view of business sustainability explores ways to reduce the carbon footprint, use resources more efficiently, and use less resources overall. But most important, it stops wasting precious time, money, and resources on processes that can hurt workers.

Keeping It Cool

Regardless of the machine tool or system, it is wise to invest time in preventative maintenance as prescribed by the manufacturer. With proper care, it is easy to keep machine tools functioning at their maximum performance level – saving shops time and money in the long run.

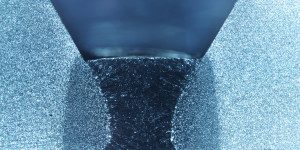

Determining Actual Grinding Productivity & Cost

By evaluating and tracking abrasive performance, combined with taking the time to select the best abrasive for a particular application, job shops and production operations can identify opportunities to significantly decrease grinding costs and increase productivity.

New Arc Process for More Efficient Welding

A new algorithm uses the high processing power, large memory, extremely fast system bus and highly dynamic wire feed speed of the latest MIG/MAG power source platform to ensure an extremely stable arc with minimal spatter.

How Engine-Driven Welder/Generators Save Space and Fuel

A diesel engine-driven welder/generator with dual-operator capabilities is one fuel-efficient machine that provides a full range of jobs and options for multiple users on the service truck or the jobsite — all without sacrificing arc quality or productivity.