Column

Filter by Process Zone:

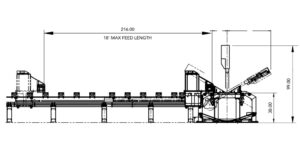

Sawing Systems Optimize Cutting Parameters and Monitor Cutting Processes

Real time monitoring systems track the performance of band saws, correcting the process to minimize disruptions.

Cost-effective Monitoring Systems Provide Thorough and Clear-cut Assessments

Make timely decisions regarding tool changes and adjustments to machining parameters with powerful monitoring systems.

Metalworking Holds Steady by Creating New Opportunities

Expansion and job growth announcements demonstrate unwavering commitment to U.S. manufacturing.

When Pretty Welds Aren’t Enough

Shops struggling with outside disruption and competitive pressures should look into robotic automation as these techniques continue to make significant advancements.

Parts Marking Guarantees Traceability and Quality Control

The integration of part marking solutions brings several advantages including durability and longevity.

Abrasives Leap Forward: Extending Product Life Spans and Enhancing Performance

Inventive and next generation abrasives are having a transformative effect in shops that rely on the products for any number of applications.

Flexible and Adaptable Machines Allow You to Compete in a Rapidly Evolving Landscape

User-friendly automated metal forming solutions are leveling the playing field for small to mid-size fabricators in several ways.

Versatile Heat Treating Systems Handle Diverse Applications

Continuous and controlled environments for the heating of metals ensure consistency and high-quality treatments and solutions.

Quickly Adapt to and Utilize Robotic Technology Via User-Friendly Programming

As robotics and automation technologies continue to advance, these systems will play an even more vital role in shaping the future of metal cutting production.

Resistance Welders are Optimized for Performance, Productivity and Cost-Effectiveness

Economical and streamlined resistance welding equipment is offered in pre-engineered as well as customized solutions.

CMMs: Indispensable Tools Ensure Precise and Comprehensive Measurement

CMMs are invaluable in industries where quality and compliance with specifications are paramount.

Five-Axis CMMs Streamline and Automate Parts Inspection and Measurement

Labor shortages, automation, and need for nimble parts inspection drive adoption of CMMs.