Column

Filter by Process Zone:

How to Determine the Diffusible Hydrogen of Mild Steel Weld Filler Material

To avoid hydrogen-induced cracking, the hydrogen level in the welding filler material must be restricted to a certain maximum level. What exactly is the method for measuring the hydrogen content of a carbon steel weld filler material?

Call Waiting? Not For Long

Randy Pearson of Siemens Industry explains why the great news for every job shop and captive department is that communication between the machine and the plant network is faster today than ever before.

In Memoriam

As the excitement, wonder and awe of the IMTS 2012 event showcases the latest advances in metalworking technology, it is with a heavy heart that Mike Riley pauses to share the sad news of the passing of a great man.

3D Lasers and Their General Application

The many applications of 3D laser processing systems make them a useful and economical tool for manufacturers everywhere. In this primer, Frank Geyer of TRUMPF not only examines their capabilities and limitations, but shares some useful tips for challenging applications and reviews some opportunities that you may not be familiar with.

Requesting the Appropriate Level of Weld Testing for Special Order Filler Materials

Welding filler metal certification, documentation and accountability is frequently a step of the nuclear pressure vessel fabrication and military shipbuilding process. Regis Geisler of Lincoln Electric explains how to select the appropriate weld testing requirements to verify quality and attest that the products being supplied meet the constituents of the required specification.

Turn-Mill or Mill-Turn… One Screen Can Say It All!

Randy Pearson of Siemens Industry explains how innovative CNC technology can now operate sophisticated multi-task machine tools with seamless transitions from mill to turn or turn to mill or both; identical look-and-feel to screens, too!

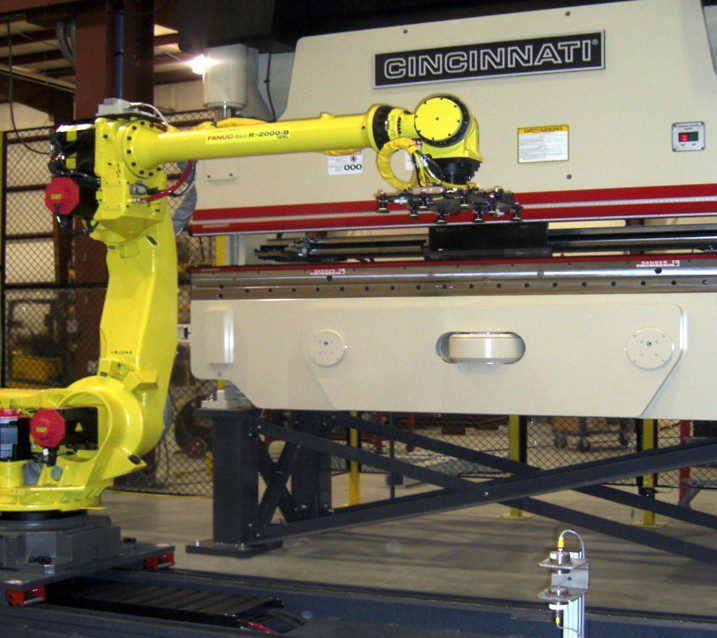

Automation: Press Brakes and Robots

Still reluctant to automate your press brakes? Here are some reasons why it is time to rethink this while you still can, because the latest robotic automation has proven it can reduce your part costs and level the playing field with foreign competition.

Our Biggest Constraint: How We Think

You buy the same equipment as your competitors. You hire from the same labor pool. The only difference is how you think. Unfortunately, you and your competitors also think the same way. So you are left to compete in a market where, from your customers’ perspective, you’re all the same. So they make decisions mostly based on price. Dr. Lisa Lang of the Science of Business explain some of the common ways our thinking goes wrong and the negative effect this wrong thinking can have on your business.

Seven Ways Supervisors Can Throw a Business Under the Bus… And Not Even Know It

Kevin Ring of Institute of WorkComp Professionals explains why supervisors must respect the role of HR, carefully convey it to employees and be trained on their role relative to HR to handle all legal and personnel issues appropriately.

Tackling the Tough Traits of Tubes

Want to eliminate all of the milling, drilling, cluster punching, coping, set-up and handling that comes with fabricating deformed, bowed and twisted tubing? Consider laser cutting.

Manufacturing Engineers: Holistic Heroes of Safety

Phil La Duke of Rockford Greene explains why the skills and tools of this engineer are essential to the creation of a safe and predictable workplace that improves process capability by reducing variation in each stage of the product lifecycle.

Trail Gas-Shielding Save the Day… Again

Trail gas shielding devices have been shown time-and-again to have a dramatic effect on weld surface mottling. Here’s why.