Column

Filter by Process Zone:

The Safety Generalist

Before discussing specialization within a particular area of safety, Phil La Duke of Rockford Greene first explores the role and duties of the one who typically owns worker safety from “soup to nuts” within a given manufacturing facility.

Never Underestimate the Importance of Weld Bead Shape

Many weld failures occur due to lack of fusion when proper attention is not given to this characteristic. Regis Geisler of Lincoln Electric shares a remedy that may help fabricators avoid such problems.

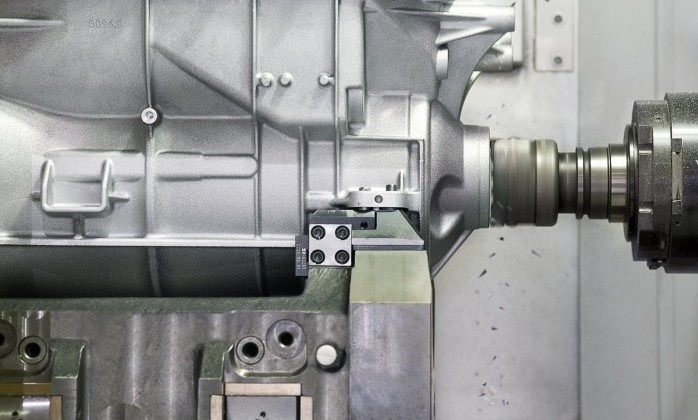

Machine/Control Simulation Means Better Results, Every Time

Ways of the Future, Here Now: As more shops seek to maximize their machining uptime, Randy Pearson of Siemens Industry explains how the ability to simulate actual cutting conditions offline offers them many competitive advantages.

Why Aren’t More Manufacturers Using Minimum Quantity Lubrication?

While the idea of sustainability is becoming better defined and understood, many manufacturers are still not taking the necessary steps to implement newer proven technologies that foster sustainability. Why?

Five Considerations When Purchasing a Fume Extraction System

In today’s market, highly skilled welders can choose where they want to work. An important factor for any company to recruit and retain skilled welders is to have a clean, healthy work environment. For this reason, it is critical for a company to have a reliable fume extraction system to maintain a clean and safe work environment.

Welding Takes to the Cloud

Always On: Cloud-based production monitoring is radically reshaping how companies track weld performance and improve their profitability.

It’s No Time to Trip

Avoiding the Dangers: How easy it is to trip when we’re blinded by our beliefs. Unless we pay attention to the dangers inherent in our fast-paced business environment that are waiting to bring us down, it’s easy to trip at the most unexpected moments.

The Death of the “Safety Guy”

When it comes to making the workplace safer, there is as much room for people who acquired their safety pedigree through years of work experience and corporate training as there is for those who acquired theirs in a university.

Modified “5-55” Vertical-Up Welding Technique Improves Bead Quality and Weld Shape

When welding with an E71T-8 electrode in structural steel fabrication and erection, here is a technique that combines the two competing priorities of being able to pause long enough at the toes to flatten out the weld and bring slag to the surface, and having a small enough weave angle in order to avoid “perforations” and inconsistent leg size.

Labor Revisited

In part one of a two-part series, guest columnist W. Brian Arthur explores the rise of the digital economy that he believes is beginning to supplant the physical economy.

Play It Safe at the Wheel

David Long of Norton Abrasives explains the various methods used for the safe operation of Type 27 depressed center grinding wheels.

How to Avoid Cracking in Aluminum Alloys

Thom Burns of AlcoTec Wire shares some tricks of the trade on some deeper insights into potential problems associated with cracking and the various characteristics of many different aluminum alloys.