Products

Manufacturing Product News

Looking for information on the latest products in the industrial world? Look no further! Check out our product overviews below.

The Latest Updates in Technology

For more than a decade, we at Fabricating & Metalworking Online have carried stories on the latest machines and equipment to hit the market. Take a look at our latest updates, go back in our archives to see what we’ve written about in the past.

Filter by Process Zone:

Quarter-Inch Right-Angle Die Grinder

Milwaukee Tool’s cordless M12 Fuel’s brushless motor is more powerful than pneumatic-powered ¼-in right-angle die grinders.

Bevel, Face & Bore Without Cutting Fluids

Hand-held Millhog bevelers from Esco Tool feature an extra-rigid blade-locking system, blades that incorporate a radical chip breaker that transfers heat so cutting fluids aren’t necessary, and a holder that enables the blade to get under the material to pull a thick chip.

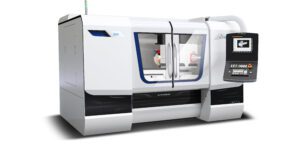

United Grinding Offers Full Range of Internal Cylindrical Grinders

A portfolio of 10 Studer machines includes several universal-type models as well as those designed for high production and for radii grinding operations. Control software enables capabilities such as in-process monitoring and the ability to string various cycle times into ISO code.

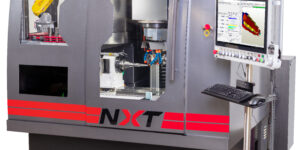

Small-Footprint Grinder with Large Work Zone

Star SU’s easily configurable NXT 5-axis grinding machine gives manufacturers the ability to run small- and large-diameter wheels to sharpen straight and spiral gash hob designs as well as disk-, shank-, and helical-type shaper cutters, Scudding cutters, and a wide range of round tools.

Increase Productivity with a Five-in-One Machine

The Elb-Schliff millGrind BL10 from Precision Surfacing Solutions (PSS): grinding, drilling, and milling in one clamping; deep grinding and, with an optional laser head, deposition welding in the other. A complete machining solution for aerospace manufacturers.

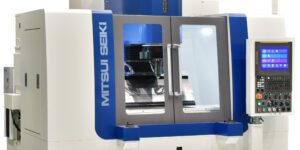

Compact Automatic Jig Grinder

Mitsui Seiki’s new-and-improved J350G grinds small- and large-diameter holes as well as multiple features using a single wheel in a continuous, automatic mode. The machine is 50% smaller than the previous model, giving manufacturers more options for shop floor usage.

Power Skiving and Gear Shaping in One Machine

A hydraulic chuck combined with a changeable back stop and slotted collet, the Mytec Hydraclamp paves the way for power skiving by enabling users to clamp different diameters and components with one hydraulic chuck.

Chamfer Cutting of Interfering Contours & Internal Gears

Apart from milling pins, there haven’t been many solutions for chamfering internal gears – a severe limitation given that roughly half the gears and shafts in a gearbox have interfering contours. Liebherr Gear Technology’s ChamferCut collision gear technology addresses this problem.

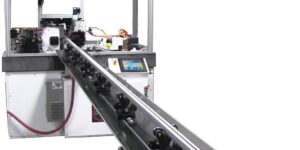

Designing a Solution for Thrufeeding Metal Tubes

Process-improvement company helps customer reduce lead times and costs by configuring an infeed/thrufeed centerless grinding machine with custom software that enabled the customer to vertically integrate.

Nine New Grinders & Sanders

Chicago Pneumatic’s CP3550 product lineup of 17 compatible finishing models allows perfect matching of applications and tools. Greater torque increases material removal rates and operator comfort while deburring, contouring, chamfering, fettling, removing seam welds, preparing surfaces, cleaning, polishing, and finishing.

LASER INTERFEROMETER VERIFIES TRUMPF’S PUNCH LASER MACHINE FASTER, MORE ACCURATELY

API’s XD Laser measures 3 DoF in one process.

READING THE DROP CUT

Step-by-step instructions for perfecting your plasma cutting technique. Similar to how an archeologist can read the history of a canyon wall, an experienced plasma cutting operator can take one look at the surface and tell you what went right, what went wrong, and how to correct your mistakes.