Products

Manufacturing Product News

Looking for information on the latest products in the industrial world? Look no further! Check out our product overviews below.

The Latest Updates in Technology

For more than a decade, we at Fabricating & Metalworking Online have carried stories on the latest machines and equipment to hit the market. Take a look at our latest updates, go back in our archives to see what we’ve written about in the past.

Filter by Process Zone:

THREE SMART TOOLS FOR SMART FACTORIES

Festo is distributing a new line of magnetic grippers and giving you the ability to design your own 2- or 3-axis industrial robot.

ONE CRANE, TWO AUTOMATION OPTIONS

Overhead crane combines lightweight aluminum rail systems with semi- or fully automated “smart” material-handling solutions.

TWO NEW PRODUCTS FROM BILSING

Ultrahigh-modulus carbon fiber composite tooling and double-blank detection for hot or cold stamping.

INVERTERS AUTOMATE STACK-FLIPPING

Machine minimizes damage to blanks and enables same die to be used for stamping left-hand and right-hand mirror-image components.

Custom Forklift Attachment Enhances Stamping Plant Productivity

Caldwell Group tool facilitates delivery of 11-to-12-ton steel coils at MiTek USA.

Welcome to the Next Decade: Metalworking in Industry 4.0

During the next ten years, more fabricators will compete with sophisticated, connected networks that apply artificial intelligence to manage data that reduces their cycle times in design to manufacturing to delivery.

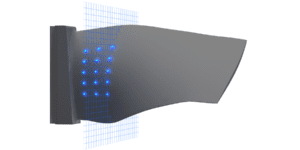

Automated Adaptive Milling

Automated adaptive blade milling from Liechti Engineering measures the workpiece in the machine and CAM software generates and optimizes a tool path that eliminates human error, optimizes productivity and ensures the highest quality result.

Intelligent Toolholder Controls the Cutting Process in Real-Time

The smart iTENDO hydraulic expansion toolholder from SCHUNK enables real-time process monitoring and control of geometry and performance data directly in the tool.

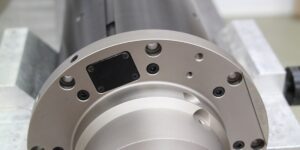

Electro-Spindle Monitors Cutting Processes in Real-Time

The e-SPINDLE from PCI / Absolute Machine Tools integrates sensors and actuators to monitor cutting processes and adjust parameters to optimize tool life and part quality.

How Pre-Emptive Replaces Real-Time

Because real-time is too late, the comprehensive Artificial Intelligence Suite from DataProphet can achieve real impact with pre-emptive actions to improve production quality and reduce defects for Industry 4.0.

Smooth Operator: Surface Finish Measurement

Take a closer look at some of the latest advances in surface roughness measurement that can help improve the manufacturing quality of parts.

Never-Before-Possible Roughness Measurement

A MarSurf GD roughness measuring station from Mahr Inc. can do profile and waviness evaluations in addition to surface roughness evaluations on larger parts or a series of smaller parts staged together – all on the same machine.