Products

Manufacturing Product News

Looking for information on the latest products in the industrial world? Look no further! Check out our product overviews below.

The Latest Updates in Technology

For more than a decade, we at Fabricating & Metalworking Online have carried stories on the latest machines and equipment to hit the market. Take a look at our latest updates, go back in our archives to see what we’ve written about in the past.

Filter by Process Zone:

Measuring Small Components

The Flying Spot SurfaceMeasure 201FS laser sensor from Mitutoyo uses a point scanning method to achieve high reproducibility, best-in-class scanning accuracy and a high data acquisition rate for inspection and reverse engineering of small components.

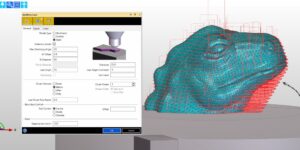

Optical Inspection of Cylinder Bore Surfaces

The Hommel-Etamic Toposcan system from Jenoptik can automatically measure the size of porosity and blow holes, stroke reversal radius, laser pocket structures, roughness of bore walls, torn and folded metal and cross-hatch angles.

More Aggressive Than Ever

Whether the stock removal involves blending, grinding, cutting, cut-off, notching or deburring, many of the newest types of abrasives are more aggressive in their surface conditioning capabilities – and in helping to reduce your operating costs. Here are some of the ways they do it.

Diamond Grinding Discs for Superior Stock Removal on Difficult Materials

Mosaic diamond grinding discs from Buehler effectively and consistently grind steel, sintered carbides, alloyed metals, thermal spray coatings and other hard materials with an improved material removal rate that reduces operating costs.

Disc Brushes for Automated Finishing in CNC Machines or Robot Cells

Ideal for automated deburring, edge filleting and surface finishing of milled, flat precision parts, Garant disc brushes from Hoffmann can also finish machining valve plates with internal labyrinths and brush down smooth surfaces on parts produced by sintering, punching, die-casting or pressing.

How to Lower the Costs of Cross Hole Deburring, Manual and Automated Honing

Ideal for use in automotive, marine, oil and gas, aerospace, pump and valve applications, long life CrossFlex honing brushes from Weiler Abrasives provide a surface finish free of metal burrs.

Stringing Out Longer Life For Aggressive Weld Cleanup

The 7 in Stringer Bead Brush from Osborn provides longer life, increased rigidity and aggressiveness for weld cleanup applications, including root and hot pass, surface preparation, deburring, pipe joining and other applications.

Single-Step Weld Blending & Grinding

Extra-heavy duty non-woven Norton Rapid Prep XHD Coarse and Medium Discs from Saint-Gobain Abrasives solve aggressive stock removal and blending challenges by removing weld lines, weld splatter, weld discoloration and blend surfaces in a single step.

How to Grind Aggressively in Corners and Other Tight Spaces

Lightweight and easy to control for less gouging of metal material, Korner flap discs from Weldcote allow the user to grind aggressively into corners, fillet welds and other tight fit areas on carbon-based steels and stainless steel.

Highly Aggressive Stock Removal For Grinding Steel, Stainless Steel

High performance 6 in Polifan Z SG Power Steelox flap discs from PFERD handle demanding grinding work, delivering optimum stock removal on high-powered angle grinders even at higher contact pressures.

Redefining Manufacturing: CAD/CAM Software

Deeper integration of smart technologies, improved simulation of machining and metal fabrication processes, and expanded additive functions highlight some of the latest advances in the CAD/CAM world that are helping shops produce better quality parts in shorter times to lower their cost to market.

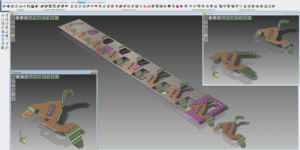

Next Steps in Progressive Die Design

VISI 2020.1 mold and die software from Hexagon improves progressive die design processes and enhances part unfolding, deburring, reverse and graphics functionality.