Products

Manufacturing Product News

Looking for information on the latest products in the industrial world? Look no further! Check out our product overviews below.

The Latest Updates in Technology

For more than a decade, we at Fabricating & Metalworking Online have carried stories on the latest machines and equipment to hit the market. Take a look at our latest updates, go back in our archives to see what we’ve written about in the past.

Filter by Process Zone:

Revolutionizing the Robotic Welding of Exhaust Components

Advanced process controls for automated MAG welding from Fronius consistently weld complex exhaust components by using high-performance electronics of power sources to adapt the arc in a controlled manner for optimum results.

Robotic Welding Consumables Reduce Downtime and Skilled Labor Tasks

By reducing the need for replacement, AccuLock R Series Consumables from Tregaskiss increase throughput and efficiency with less human interaction and fewer opportunities for errors in the welding cell.

Hire a Robot Welder by the Hour

There are no installation costs with BotX Welder from Hirebotics, and shops pay only for the hours the system actually welds, thereby enabling them to hire and fire BotX as their business needs dictate.

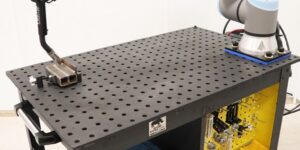

Mobile Plug-and-Play Cobotic Welding Cart Runs Off Wall Outlet

Powered by a UR10e collaborative robot from Universal Robots, the Vectis Cobot Welding Tool from Vectis Automation is a low-risk, low-cost, easy-to-use system that boosts productivity by reducing the learning curve, deployment time and cost of robotic welding.

Movers and Shakers: Conveyors

In the dawning Age of the Smart Factory, the workhorse of the shop floor is getting sleeker, smarter, more efficient and much more flexible in moving material from one point to another in more applications than ever before.

Vacuum Cleaning System for Below-Floor Mechanical Metal Chip Conveyors

To reduce cleaning time and increase machine tool uptime, the Central Vacuum Cleaning System from VAC-U-MAX collects and deposits wet or dry cast iron, steel, aluminum and composite chips, abrasive materials and metal debris onto existing below-floor mechanical chip conveyors.

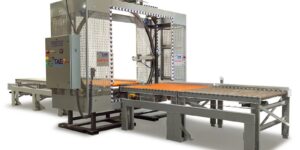

Automated Orbital Wrapping with Multi-Pallet Accumulation Zones and Integrated Weighing

Multi-pallet accumulation zones and integrated load cells on the fully automated Perfect Storm wrapping system from TAB Industries improve efficiency, keep lift trucks from being idle, and eliminate extra freight charges and delays due to inaccurate weights.

Automated Chip Handling and Coolant Filtration for Machining Operations

The flexible, cost effective, self-cleaning EcoFilter conveyor and filtration system from Jorgensen easily fits the existing coolant tanks of machining center and lathe envelopes and can be retrofitted with a kit.

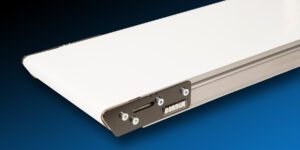

Automated Handling of Small to Medium-Sized Parts

Strong, fast and flexible 2200 Series low profile belt conveyors from Dorner are engineered for part transfers to part accumulation, precision part movement, small part handling and positioning, part/package infeed and outfeed, automated and manual assembly.

Cabinet Oven for Annealing

For annealing or normalizing processes, No. 1049 is a 1,050 deg F two-drawer cabinet oven from Grieve that has 800,000 BTU/hr installed in a modulating natural gas burner, while a 10,000 CFM, 7.5 hp recirculating blower provides horizontal airflow to the workload.

Next Steps in Weld Fume Source Capture

The highly effective, efficient and versatile FV-500-20 weld fume source capture system with Ergomax fume guns from FumeVac meets stringent ACGIH guidelines and OSHA standards for mitigating harmful welding fumes, including manganese and hexavalent chromium.

The First Switchable Adjustable Ring Mode Fiber Laser

Ideal for high-volume automotive welding, the high-power HighLight FL-ARM dual fiber output laser can sequentially power two separate workstations or processes.