Products

Manufacturing Product News

Looking for information on the latest products in the industrial world? Look no further! Check out our product overviews below.

The Latest Updates in Technology

For more than a decade, we at Fabricating & Metalworking Online have carried stories on the latest machines and equipment to hit the market. Take a look at our latest updates, go back in our archives to see what we’ve written about in the past.

Filter by Process Zone:

Effective Measurement and Control of Shop Tooling

The Smile universal presetting and measuring machine from Zoller accurately measures standard tools easily and quickly, while their Smart Cabinets precisely track the exact location of any given tool, who checked the tool out, for which machine and to which job.

Highly Productive Manufacturing of Gears with CNC Turning Centers

The gear hobbing unit from WTO makes it possible to manufacture gears with different geometries and requirements on a turning center. Its counter support is removable so that the cutting area is easy to reach and changing the cutting tool is fast.

Create and Share Step-By-Step Visual Work Instructions to Increase Productivity

By implementing VKS software, shops can reduce defect levels, increase their productivity and profitability, simplify their internal processes, gain full visibility and allow employees on the shop floor to follow the best procedures and capture/document tribal knowledge.

Innovative Metrology and Force Measurement Systems

The HDV300 Horizontal Digital Video Comparator from Starrett combines vision and optical comparator technology with a uniquely designed interchangeable lens mounting system, go/no-go digital overlay capability directly from part CAD files, and real-time video edge detection.

Effective Machining of Heat Resistant Super Alloy Materials

JX1, JP2, and new JX3 inserts from NTK Cutting Tools use Bidemics material for increased toughness to effectively machine heat resistant super alloy materials like Inconel 718 and Rene 65 at speeds of 1,600 SFM for increased productivity.

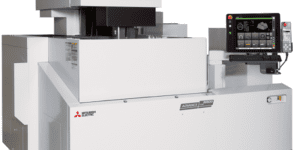

Wire EDM for Production Machining of Larger Parts

The MV2400-ST wire EDM from MC Machinery can perform submerged cutting up to 16.5 in deep, with an annealing length over 21 in to thread the maximum workpiece height for a broken wire recovery at the start point and through the gap if needed.

Easy, Fast and Safe Way to Hold Round or Cylindrical Workpieces

For quicker, safer tool changes and suitable for tapped holes or T-slots, the Multi-Quick 60 S Clamp and Multi-Quick 100 S Clamp from Lenzkes offer a horizontal and vertical adjustable ranges and high clamping pressures with low torque.

Forming Rifling Grooves in Gun Barrels

The custom DeHoff G560-B1 machine tool from Kays Engineering can machine barrels from 17 caliber up to 50 caliber with a slide travel of 60 in and a pneumatically-operated chuck with programmable “twist rates.”

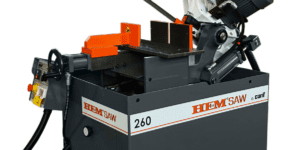

Space-Saving, Durable Horizontal Band Saws for Accurate Cuts

The 260 BSA metal cutting double-miter pivot band saw and the H90A-1 metal cutting horizontal-pivot band saw from HE&M Saw provide accuracy and durability in a space-saving design.

Increase Machine Utilization with Advanced Tool Presetting and Inductive Shrink Fit Systems

Microset tool presetting machines from Haimer reduce set up times by up to 70 percent and streamline tool setting processes with accuracy and process reliability from one operator to the next. Their Power Clamp machines provide 360 deg gripping torque with repeatable balance at the touch of a button.

Portable Dot Peen Marking Device for Round Surfaces, End of Parts and More

The MarkinBOX Patmark battery-operated cordless part marker from E.L. Simeth | MB Metal Technologies uses a solid carbide pin to mark on materials up to 62 RC, easy-to-use software that manipulates the size, depth and speed of each mark, and adjustable or fixed quick-change fixtures that hold it to the part with magnets, clamps, etc.

Superior 4+1 Five-Axis Machining of Parts for Aerospace, Medical, Mold Making

The UNi5X-400 5-axis CNC vertical machining center from Chevalier Machinery is integrated with a two-axis rotary trunnion table with a heavy duty three-piece, cross-roller bearing that provides excellent part loading and machining capability and ±10 in accuracy for the A-axis for high precision and productivity machining.