Products

Manufacturing Product News

Looking for information on the latest products in the industrial world? Look no further! Check out our product overviews below.

The Latest Updates in Technology

For more than a decade, we at Fabricating & Metalworking Online have carried stories on the latest machines and equipment to hit the market. Take a look at our latest updates, go back in our archives to see what we’ve written about in the past.

Filter by Process Zone:

Simultaneous Control Compact 5-Axis Machining Center for Medical Equipment

The compact Xion Alpha 5-Axis simultaneous control machining center from Sugino is perfect for precision micro-machining of medical equipment and high speed, high quality machining of fine free-form surfaces on small diameter tools, impellers, turbine blades, lens molds and electronic parts weighing up to 15 kg.

Rigid Telescoping Tube Clamp with Quick-Release Handle for Medical Devices

The Telescoping Tube Clamp from Stafford provides superior holding power while letting users change the length of their nested tubing with infinite adjustability and locking without damaging the tube.

FABTECH 2018: Welding, Tube & Pipe

The 2018 edition of FABTECH will be one of the largest metal fabrication events ever at the Georgia World Congress Center in Atlanta from November 6-8. Here are technical reviews of some of the machinery, tooling, systems and accessories that will be exhibited to help you navigate the show floor and manage your time while you’re there.

Hybrid Additive Manufacturing of Dissolvable Metal Components for Medical Implants

UNL is using a LENS 860 Hybrid Controlled Atmosphere system from Optomec for high quality additive and subtractive processing of magnesium to develop dissolvable components for next-generation medical implants.

Scanning Slit Laser Beam Profilers for Medical Engineering

Ophir NanoScan 2s scanning slit profilers from MKS Instruments instantly measure beam position and size with sub-micron precision for CW and kHz-pulsed lasers by using moving slits to measure beam sizes from µm to mm at beam powers from µW to kW.

Optical Surface Metrology Delivers New Insights into Surface Structures and Processing for Medical Applications

MarSurf CM systems from Mahr Inc. provide micron and nanometer resolution surface finish and micro-geometry information, including 2D and 3D surface roughness, bearing area, flatness, depth, volume and much more.

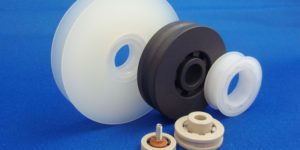

Non-Magnetic Bearings Prevent Static and Noise in Medical Equipment and More

Anticorrosive, chemical resistant, nonmagnetic and lubrication-free plastic bearings from Kashima are hand-machined to the highest precision standards to meet the varying and long-term demands of medical equipment.

Automatic Lathe Tooling to Make Screws and Pins for Medical Applications

The Citizen tool program from Heimatec that includes both live and static tools for most Citizen lathes incorporates the highest quality bearings, ground gear components, spindles, and housings to produce superior tools with maximum rigidity.

Manufacturing Structurally Sophisticated Implants Without Supports

By integrating their Sapphire 3D printing system with Flow print preparation software and Intelligent Fusion technology, Velo3D can manufacture structurally sophisticated implants without supports to ensure better patient experience and lower cost.

How to Meet Tough Finishing Demands on Pharmaceutical Projects

Instant Polish flap discs from Walter Surface Technologies boast powerful polishing properties and superior engineering that easily achieves No. 8 mirror finishes in a single step to save time and money.

Linear Encoders for Ultra-High Accuracy in Medical Machining

LIF 400 series linear encoders from Heidenhain improve contamination resistance with a position noise value of 0.6 Nm at one MHz and a low interpolation error down to ±12 Nm.

Economic Upgrade of Small Vertical Machining Centers for Complex Medical Device Work

The ultra-high precision pL Lehmann 5-axis rotary table TAP from EXSYS Tool can upgrade a small vertical machining center to do complex medical device work up to a cube of approximately 5.9 in without the expense of a new machine.