Products

Manufacturing Product News

Looking for information on the latest products in the industrial world? Look no further! Check out our product overviews below.

The Latest Updates in Technology

For more than a decade, we at Fabricating & Metalworking Online have carried stories on the latest machines and equipment to hit the market. Take a look at our latest updates, go back in our archives to see what we’ve written about in the past.

Filter by Process Zone:

Moving Head CNC EDM Drilling Machines for Aerospace Parts

Easy automatic drilling of holes of different depths, smooth motion and stability, and long unattended operations make the Yougar YGS CNC Moving Head EDM from Absolute Machine Tools superior to fixed-head, moving-table style EDM drills.

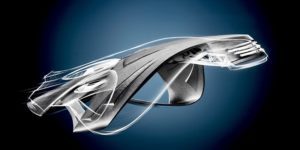

Advanced Precision Machining of Complex Aerospace Components

The 5-axis Liechti go-Mill 350, Mikron MILL P 800 U ST and FORM 200 die-sinking EDM from GF Machining Solutions generate flawless surface finishes on complex part shapes found in turbines and cell components for avionics.

How to Cut Finishing Times of Aircraft Blisks From Several Days to a Few Hours

By mounting single workpieces to the inner dome of the processing bowl, the redesigned CM vibratory system from Walther Trowal allows deburring and general surface improvement of components with diameters up to 980 mm.

Oscillating Laser Beam Opens Up Applications for Aerospace Parts

The welDYNA scan head from SCANLAB opens up countless new possibilities in aerospace processing where thick metal parts and fiber-reinforced plastics must be cut more quickly and cleanly.

Metric-Sized Metal Shapes and Parts for Aerospace Applications

Metric metals from Parker Steel include 17-PH round bar stainless steel and 360 brass round and hex bars for high strength, superior corrosion resistance and easy machining that is suitable for bushings, circuit board relays, switches, nuts, bolts, pump shafts, fixtures and other parts used on aircraft.

Gas Technologies and Powder Storage Advance the Quality of 3D Printed Aerospace Metal Parts

Ideal for powder-bed laser fusion processes, the portable ADDvance O2 precision atmosphere monitoring system and powder cabinet from Linde precisely controls O2, temperature and humidity levels in the powder process chamber and storage atmosphere.

Ultrasonic Cleaning of 3D Printed Aerospace Parts

The compact 20 gal plug-and-play Omegasonics 1900BTX ultrasonic cleaning machine from Plural Additive Manufacturing uses a specially formulated blend of aerospace quality polyphenylene sulfide to clean parts 3D printed on fused filament fabrication machines from 3ntr.

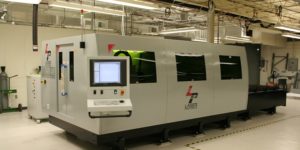

Laser Cut Highly Reflective Aerospace Metals Up to Four Times Faster

The Titan FX large-format laser cutting system from Fonon uses an advanced direct drive magnetic motion system, innovative CleanCut laser technology and adaptive thin-to-thick beam shaping technology to automatically balance high acceleration, cut speeds and positioning with maximum accuracy.

Vacuum Furnaces for Aerospace Brazing and More

Customized MetalMaster and TITAN vacuum furnaces from Ipsen provide precision gas quenching for aerospace brazing and other high vacuum applications, particularly with thin section parts and lighter pieces.

Wet Blast System for Aircraft Engine Components

The WBS/Guyson Model 72×36 Dual Operator System is used for cleaning and surface preparation of aircraft engine components up to 55 in long and 24 in diameter.

Robotic Systems Integration for Aircraft Manufacturing

Large-scale automation from Genesis Systems features KUKA robots and mobility equipment for non-destructive inspection, laser processing, mobile robotic platforms, IIoT connectivity for press tending and cell control, and manipulators used in commercial aerospace and aircraft applications.

How to Prove-Out Large Aerospace Part Form and Functionality Before Building

Powered by NVBOTS, the SAAM system from Cincinnati Incorporated uses fused filament fabrication technology to 3D print plastic parts directly from a CAD design so that designers can prove-out part form and functionality while saving material and time prior to building out full-scale parts on a BAAM.