Products

Manufacturing Product News

Looking for information on the latest products in the industrial world? Look no further! Check out our product overviews below.

The Latest Updates in Technology

For more than a decade, we at Fabricating & Metalworking Online have carried stories on the latest machines and equipment to hit the market. Take a look at our latest updates, go back in our archives to see what we’ve written about in the past.

Filter by Process Zone:

Innovative Cold Former Minimizes Changeover Time

The seven-station COLDmatic CM 725 cold former from Hatebur produces up to 180 parts per minute with fast changeover times of only ten to 15 minutes on high precision parts from 8 mm to 125 mm long with a wire diameter up to 22 mm.

Bladderless Fluid Forming of Seamless, High Pressure Metal Tubing

The FormBalancer FB42 from FluidForming Americas can create larger single prototypes or oversized high-run parts of titanium, aluminum, stainless steel, and copper that require an extra-large 47 in square forming table capacity.

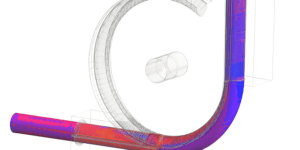

Simulation of Tube Embossing and Bending for Roll Formers

Roll forming procedures, pre- and post-processing steps can be optimally calculated to improve the forming process as a whole using COPRA FEA RF software from data M, which visualizes and verifies the production process within a virtual environment to prevent deviations during production.

Economical Spray Washer for Very Large, Heavy Machined Parts

Large gears, aviation components, large molds and dunnage parts can be loaded with an overhead hoist crane onto a rotating table for cleaning in the Ransohoff Mega Jet Pressure Blast from Cleaning Technologies Group, where the high pressure spray impingement is manipulated by hand to the various geometries of the parts.

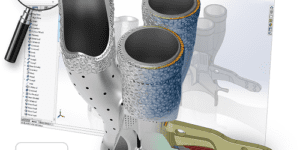

How to Optimize Additive Manufacturing Designs

3DXpert for SolidWorks from 3D Systems is an integrated system that gives designers a direct path for preparing and optimizing their SolidWorks designs for both plastic and metal additive manufacturing, creating the design freedom to produce complex geometries, lightweight parts without compromising strength, and apply surface texture to deliver functional or aesthetic benefits.

Economical High Precision Bending

Ideal for entry into precision bending, the TruBend 3100 press brake from TRUMPF is simple to operate, accurate and reliable, with a multi-axis backgauge that can move across the entire 118 in length of the machine bed for unrestricted use when bending complex part geometries at the ends of the machine.

Economical Ironworkers and Punch Presses for Full Fabrication of Standard and Custom Jobs

The two-cylinder/two-person operation of the MM Series Complete Five-Station Fabrication Center from Kalamazoo Metal Muncher allows the punch and shear end to be operated separately, independently and simultaneously at full capacity and speed. Their GB Series Hydraulic Punch Press can also be fitted with special tooling to allow shearing or forming.

Cabinet Oven for Heating Tubular Aluminum Parts

The No. 890 from Grieve is a 350 deg F electrically heated cabinet oven with a motor operated vertical lift door.

Tooling for Automated Cross Hole Deburring

COFA-X tooling from Heule Tool consistently removes burrs from interior uneven bore edges with large intersections in valves, fittings, hydraulic manifolds and more, reducing costs and improving cycles times for operations that were previously possible only with manual deburring.

Slash Cutting Material Costs When Machining Turbine Components

The M2471 copy milling cutter from Walter couples high metal removal rates, even on low performance machine tools, with lower cutting material costs resulting from eight cutting edges (four per side) per insert.

Large L/D Ratio Drills Guarantee Excellent Feed Rates with Controlled Chip Removal

The GARANT MasterSteel FEED 8xD and 12xD high performance solid carbide drills from Hoffmann Group guarantee excellent feed rates through a special innovative geometry with stable cutting edges and a large clearance in the center.

Cutters and Inserts for Machining Turbine Components Used in Power Generation

The R217/R220.28 cutter from Seco Tools performs cost effective face milling, slotting and contouring in ISO M and ISO S materials, as well as some difficult-to-machine ISO P materials, such as martensitic stainless steel.