Products

Manufacturing Product News

Looking for information on the latest products in the industrial world? Look no further! Check out our product overviews below.

The Latest Updates in Technology

For more than a decade, we at Fabricating & Metalworking Online have carried stories on the latest machines and equipment to hit the market. Take a look at our latest updates, go back in our archives to see what we’ve written about in the past.

Filter by Process Zone:

CNC Milling & CAD Training Videos

The Training Professor Video Series from BobCAD-CAM covers basic programming techniques, then advances into gouge checking, adaptive toolpath programming, tapered thread milling and other complex applications.

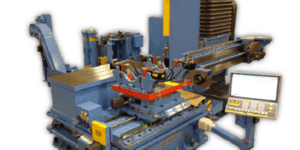

Modular Systems for Custom Profile Machining

Special modular systems from Suhner can be created for complete profile machining applications of various large volume parts or long sections from multiple sides that often fit poorly or not at all on standard machine tools.

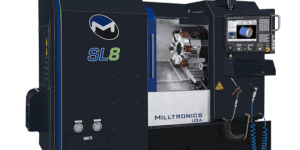

Next Generation Slant-Bed CNC Lathes for Quick Turnaround Jobs

SL-II Series CNC lathes from Milltronics are fast, accurate and affordable true slant bed CNC lathes with robust roller guideways for superior accuracy and heavy cutting that anyone in a small to medium size shop can run to get jobs out the door in a hurry.

Flexible 5-Axis HMC For High Productivity and Absolute Precision

The FP 4000 5-axis horizontal machining center from Heller Machine Tools uses twin drives in the Z axis for heavy duty cutting, combined milling and drilling operations, or 5-sided machining in a single setup for contract manufacturing or tool and die work where 5-axis milling is needed for productivity and process dependability.

Innovative, Compact HMC With Column Traverse Structure

The KIWA-Japan Triple H40 Horizontal Machining Center with a Column Traverse Structure from Methods Machine Tools supports the flexible mounting of various fixtures and rotary tables based on the application.

Effective Drilling of Complex Hole Patterns

The redesigned DeHoff 2072TC gundrilling machine with 5-axis capability from Kays Engineering mounts a gundrilling spindle on a traveling column for X-axis and Y-axis movement, with a CAT 40 spindle mounted on the traveling column for secondary milling and tapping operations.

Large Part Precision Machining Services

Coldwater Machine Company performs precision machining with tolerances of +.0003 in for prototype creation or contract manufacturing of large jigs, fixtures, lift devices and material handling equipment for the energy industry made from a variety of materials.

Quill Spindle HMC Produces Large, High Precision Bores for Energy Applications

The HU100 Quill Spindle horizontal machining center from Mitsui Seiki USA is well suited for boring of gas field valves and fittings, in addition to other fluid transfer components up to 60 in diameter and weighing up to 6,600 lb.

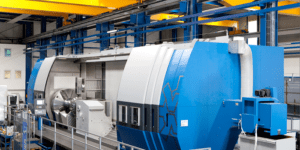

Machining Turbine Shafts for Gas Power Plants

The mpmc 2000S machining center from Weingärtner reduces machining time by two-thirds on giant turbine shafts that are 2 m diameter, weigh up to 60 tons and feature innovative component geometries used in gas or vapor turbine power plants.

5-Axis Machining of Gas Turbine Blades for Power Generation

The LX 251 from Starrag performs efficient, complete five-axis machining of complex, high-tech turbine blades in one clamping for consistent reproducibility of workpieces that is critical when manufacturing fan blades.

Machining of Gas and Steam Turbine Casings and More

The PXG multi-tasking gantry milling machine from SORALUCE maximizes productivity and minimizes set-up time for turning, milling, boring, drilling and threading complex gas and steam turbine casings, CHP motors, parts used in the construction of machinery for the energy industry, and the general machining of other large workpieces.

Heavy Duty 5-Axis Machining of Generator Turbine Components

The INTEGREX i-630V/6 multi-tasking machine from Mazak uses fast, high torque milling and turning spindles for 5-axis and trochoidal machining of generator turbine components and other large, highly complex parts in the shortest cycle times possible.