Products

Manufacturing Product News

Looking for information on the latest products in the industrial world? Look no further! Check out our product overviews below.

The Latest Updates in Technology

For more than a decade, we at Fabricating & Metalworking Online have carried stories on the latest machines and equipment to hit the market. Take a look at our latest updates, go back in our archives to see what we’ve written about in the past.

Filter by Process Zone:

Grinders for Difficult Applications in Limited Space on Oil and Gas Platforms

Lightweight FA-20 series 2 in angle grinders and die grinders from Fuji Air Tools feature a distinctive low profile grinding head design that is particularly suited to metal grinding for mold maintenance, weld bead removal, deburring and chamfering on oil and gas platforms and in other metalworking applications.

Efficient Turning and Milling of Large Gear Rings and Other Oil and Gas Components

With a spindle design that uses flexible feeds and speeds to cut a variety of materials with excellent surface finish and impressive metal removal rates, the LB3000 EX-II CNC horizontal lathe from Okuma can efficiently turn and mill pipe-type parts with a through-hole diameter that accommodates larger parts.

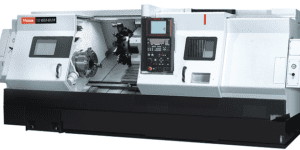

Multi-Tasking Productivity in Machining Large Parts for Oil and Gas

The multi-tasking QTN 450M turning center from Mazak performs milling, drilling and tapping operations for highly efficient single-setup part processing to boost productivity and reduce cycle times when machining large diameter, shaft-type parts used in oil and gas.

Superior Machining of Large, Complex Parts for Oil and Gas Machinery

Using superior vibration absorption for improved part surface quality and finish, the Mycenter-HX800G horizontal machining center from Kitamura Machinery delivers the high precision, accuracy and repeatability required for producing close tolerance parts from the toughest of materials.

Effective Machining of Long Pipes and Rods for Offshore Plants and Oil Exploration

The PUMA 1000/M from Doosan boasts the strongest cutting capacity in its class, has a maximum machining diameter of 39 in and a maximum machining length of 80 in, and provides a wide spindle through-hole of up to 22 in for processing long pipes and rods.

Weld Purging of Pipes for Oil and Gas Operations

QuickPurge Systems from COB Industries remove the need to fill complete pipes with an inert gas, reduce the space to be purged, and cut purging time dramatically for huge savings in time and gas costs.

How to Regain up to 95 Percent of Lost Productivity for Tip Changes

TOUGH LOCK HDP Contact Tips from Tregaskiss last six times to ten times longer than copper and chrome zirconium tips that often need to be replaced twice as frequently during pulsed MIG welding due to its high heat input.

Fume Extraction Gun for Large Weldments, Confined Spaces

The 300 amp Clean Air Fume Extraction MIG gun from Bernard reduces smoke at the source with a small vacuum chamber that provides good joint access and visibility, along with a 360 deg vacuum hose swivel on the rear of the handle for improved flexibility that reduces operator wrist fatigue.

Precision Shot Peening for Automotive/Marine Applications

The small footprint RSSA-6 is a custom precise shot peening machine from Guyson that meets AMS-2431/ 2E specifications.

Early Warning Device Prevents Injuries on Busy Shop Floors

The patented EdgeAlert Open Gate Alarm System from Wildeck will signal an open gate condition with a highly visible flashing light and a loud audible alarm to prevent employees from falling and sustaining severe injuries.

Welding Equipment for Pipe and Tube Fabrication on the Jobsite

The Dynasty 280 DX with CV from Miller Electric includes Auto-Line technology and can TIG weld 0.012 in to 3/8 in aluminum and 0.004 in to 3/8 in steel with superior arc performance. It can TIG weld with AC waveforms, including advanced squarewave, soft squarewave, sine wave and triangular wave.

How to Reduce Eye Strain by Optimizing Contrast and Clarity in Welding and Light States

To achieve the perfect weld, operators must be able to clearly see their work. This new lens technology from Miller Electric optimizes contrast and clarity in both welding and light states so that operators see natural color tones and get a crisp, high-definition view of the workpiece.