Products

Manufacturing Product News

Looking for information on the latest products in the industrial world? Look no further! Check out our product overviews below.

The Latest Updates in Technology

For more than a decade, we at Fabricating & Metalworking Online have carried stories on the latest machines and equipment to hit the market. Take a look at our latest updates, go back in our archives to see what we’ve written about in the past.

Filter by Process Zone:

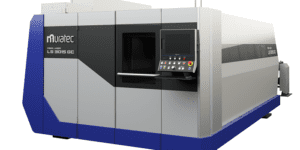

Economical Fiber Laser Cutting of Ferrous and Non-Ferrous Materials

The compact LS3015GC fiber laser cutting system from Murata Machinery uses an integrated flying optics system with internal controls that monitor laser output, laser beam and light reflection for superior cutting of ferrous and non-ferrous materials, including steel, stainless steel, aluminum, brass and bronze.

Highly Efficient 3D Laser Cutting of Chassis and Complex Vehicle Body Parts

The virtually wear-free JENOPTIK-VOTAN BIM 4 kW laser cutting machine from JENOPTIK can cut a circle or other standard contour in just one second, with repeat accuracy up to 50 μm in optimal conditions.

Ultra-High Speed Fiber Laser Cutting for Trailer Body Manufacturers

The Electra FL 3015 8 kW fiber laser cutting machine from LVD Strippit maintains 2G acceleration while cutting to produce high quality, high accuracy cuts in simple to complex configurations on ferrous and non-ferrous materials.

High Precision Coil Processing Lines for Fineblanking Brake System Components and More

The Fineblanking Edition HD straightener in high precision coil processing lines from COE Press Equipment addresses coil set and crossbow issues necessary to achieve the flatness required for producing near net shape blanked parts.

Powerful, Flexible Fiber Laser Cutting for Trailer Body Manufacturers

Using HighSpeed Eco cutting technology with a newly designed bi-flow nozzle that minimizes nitrogen consumption while maximizing productivity, the TruLaser 5030 fiber laser from TRUMPF can process complex contours and power through mild steel up to 1 in, stainless steel up to 1.5 in and aluminum up to 1 in.

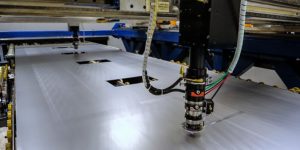

Multi-Mode Feed Capability Increases Coil-Fed Laser Blanking Speeds

With Continuous Mode (On the Fly Cutting) capabilities on coil-fed laser blanking systems from LaserCoil Technologies, users can choose either Feed Index Mode (Stop/Start) or Continuous Mode for the best production run rate and reliability.

Innovative Flame Resistant and Breathable Welding Jacket

Ideal for welding operations, assembly and metal fabrication, the innovative FR flame resistant welding jacket from Magid features ANSI Cut Level 4 sleeves and a breathable FR mesh back panel to help prevent heat exhaustion and provide protection while allowing body heat to escape so workers stay cool.

High Power Scanning Head for Continuous Large Area Welding, Additive Manufacturing or Volume Cladding

For high power fiber, disk, CO2 and diode lasers using collimated beams up to 48 mm diameter, the FiberScan HR scanning head from Laser Mechanisms can deliver 20+ kW of laser power to any point within the system’s field of view.

View and Monitor the Submerged Arc Welding Process in Full HD

The compact iShot Weld-i SAW HD weld monitoring video camera system from InterTest can verify torch positions, wire feed orientation and welding part alignment during submerged arc welding applications.

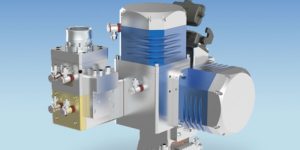

Advanced Flow Regulator Delivers Reliable Control in Laser Assist Gas Supply Applications

Ideal for bulk and micro bulk supply systems, fiber laser assist gas supply, and assist gas delivery systems from high pressure sources, the ultra-high flow 67B Series regulator from CONCOA provides steady and reliable control for delivery pressures up to 750 psig and flow rates up to 24,000 SCFH.

Nickel Alloy Welding Wire for Trouble-Free, High Quality Work in Demanding Environments

Innovative nickel alloys from Sandvik Materials Technology achieve greater consistency between heats and batches and represent a real milestone for welding applications.

Next Steps in Welding

Here are some of the latest advances in welding systems, filler metals and accessories, PPE and more that can help shops increase their welding productivity, improve process quality and safety, and reduce their overall operating costs.