Products

Manufacturing Product News

Looking for information on the latest products in the industrial world? Look no further! Check out our product overviews below.

The Latest Updates in Technology

For more than a decade, we at Fabricating & Metalworking Online have carried stories on the latest machines and equipment to hit the market. Take a look at our latest updates, go back in our archives to see what we’ve written about in the past.

Filter by Process Zone:

Abrasives, Brushes and Power Tools for Metal Finishing

Files, burs, brushes, grinding and cutting wheels and power tools from PFERD can increase shop productivity, reduce labor and resource costs, improve operator health and safety, and help improve overall process optimization.

High Speed Intelligent Laser Cutting Reduces Operator Dependency

By integrating Intelligent Setup and Monitoring Functions, the high speed, high accuracy OPTIPLEX 3015 Fiber III from Mazak Optonics simplifies operations to reduce operator dependency.

Advanced Filler Metals for Aluminum MIG Welding, Stainless Steel and Gas-Shielded Flux-Cored Welding

Advanced filler metals from Hobart Brothers are ideal for aluminum MIG welding, stainless steel, gas-shielded flux-cored welding and more.

Press Feed Equipment Minimizes Material Scrap

The Zig-Zag servo feed from Dallas Industries has a one, two or three-out capacity with the servo feed index cycle made simultaneously with the cross-slide lateral travel, producing a diagonal stock movement in the automatic mode that minimizes the scrap generated when stamping out circles. The manual mode has forward or reverse indexing and cross-travel indexing.

Remote Control of Engine-Driven Welder/Generators Without a Control Cord

Miller Electric has expanded their ArcReach remote control technology to Trailblazer 325 power sources and Big Blue 600 Air Pak, 800 Duo Pro and 800 Duo Air Pak models for complete control of welding parameters at the weld joint without a control cord.

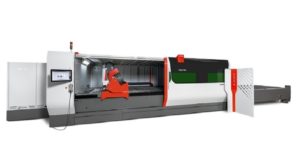

Fiber Laser Cutting of Sheets and Tubes at Unrivaled Speeds

The ByStar Fiber 10 kW laser cutter from Bystronic is ideal for shops that want unrivaled speeds in cutting thin sheet metal from stainless steel, through to aluminum and mild steel, right up to non-ferrous metals, such as copper and brass.

Servo Presses for Near-Net-Shape Fine Blanking, HSLA Blanking, High Productivity

Versatile DSF Series Servo Presses from AIDA-America can improve virtually any stamping operation through increased productivity, improved part quality, increased die life and reduced maintenance.

Fast Cutting Abrasive Discs for Heavy Stock Removal

New depressed-center grinding discs, cut-off discs and flap discs from Osborn are available in aluminum oxide, zirconia and ceramic abrasive types that provide fast cutting, heavy stock removal, long service life, application material versatility and smooth finish.

Blending Disc Eases Finishing Applications in Hard-to-Reach Areas

For exceptional performance on steel, stainless steel and aluminum alloys, the Blendex U Turbo blending disc from Walter Surface Technologies uses a heat-resistant non-woven matrix that helps provide a more consistent finish without smearing. The self-sharpening grains also allow for high material removal on many different surfaces.

Custom Grit Blasting Systems for Effective Finishing

The Dual Expanded Two-Station RXS-400 System from Guyson with a twin spindle feature that allows for two-part flow is designed for grit blasting medical implant devices in a small footprint with simultaneous dual operation.

One Fine Surface: Getting Into Gears

Take a closer look at how these innovative, flexible and highly productive gear grinding and shaping systems reduce changeover times and floor space required for job shops competing in the hypercompetitive aerospace, automotive and other high precision sectors where speed and costs are crucial.

Advanced Cold Work Premium Tool Steel for Blanking and Forming AHSS Parts

Hitachi SLD-i cold work premium tool steel from Diehl Tool Steel is ideal for blanking and forming AHSS parts and minimizes heat treat deformation to lower tooling costs. It exhibits better wear and toughness than D2 when used for forming and trim sections, and better wear than 8 percent Cr steels for specific draw sections of large automotive dies.